0

Companies around the world, from major manufacturers down to your local grocery store, all share a common struggle: efficiently managing the movement of products and people. Business may slow down because storage isn’t organized, or forklift drivers aren’t sure which way to go. Every company could benefit from better organization, workflow, and safety.

Creating a Visual Factory with the 5S System

0

The term “visual factory” refers to an approach to lean manufacturing processes based on visual information throughout the workplace. A visual factory uses a system of communication tools to share information at the time and place it is needed.

0

To gain a competitive edge, many companies have adopted lean manufacturing (or lean thinking) as a keystone for success in today’s global market. Lean manufacturing has enabled businesses to increase production, reduce costs, improve quality, and increase profits by following five key principles

0

The global market places significant pressure on businesses and other organizations to increase efficiency, improve profits, and reduce costs as consumers simultaneously demand lower-cost and better quality goods. In response, many lean manufacturing tools and methodologies have been developed to help businesses meet these demands.

Advantages of Lean Manufacturing

0

Womack and Jones, in their book Lean Thinking, define lean manufacturing as “a systematic approach to identifying and eliminating waste.” When properly implemented, lean manufacturing provides many advantages, which include improving flow (material, people, information, and work) and eliminating waste.

0

Improving manufacturing efficiency requires eliminating waste. What is waste? Anything that is not adding value to the product or service. This value must also be value that the customer is willing to pay for; any added cost or effort that the customer is not willing to pay for is also waste.

Continuous Improvement Ideas for the Workplace

0

Success in today’s competitive market requires constant innovation and a vision focused on continuous improvement. When first considering continuous improvement, it can be hard to know where to start, but here are some helpful tips that should make it easier.

0

There is more to implementing Kaizen than we can include on a single web page. However, the following serves as an overview of introducing Kaizen into an American workplace. For most American companies Kaizen involves a significant change in the corporate culture. This is key.

0

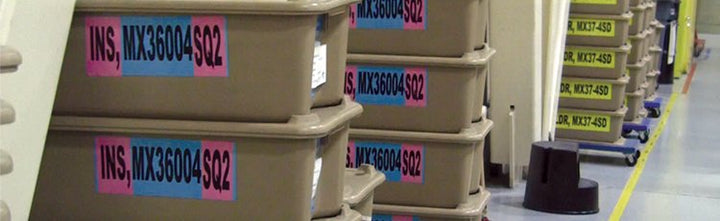

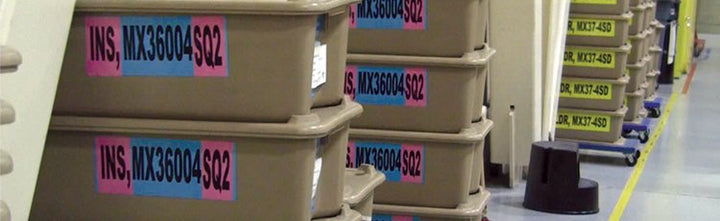

Product identification is a broad category of labeling that includes functions such as product traceability, brand protection, and various information labels. With a rapidly changing business environment and constant threats from theft and counterfeit products, product identification labeling is critical.

Are Your Safety Signs Seen by Everybody?

0

Our society has become inundated with images of safety signs—on public transportation, in the workplace, in stores, on products, on equipment, and so much more. Unfortunately, these warning, danger, and general safety signs are not always easy to read and contain so much information that they are often not understood or simply ignored.

How to Label Your Facility for Safety

0

Before beginning work, it’s crucial to evaluate your facility for safety hazards. Consistent and effective labeling, in accordance with OSHA and other industry regulations, is essential to prevent workplace injuries, costly downtime, workers’ compensation claims, and fines.