Creative Industrial Labeling Ideas for Organized Workspace

In industrial workspaces, organization and clarity are critical for smooth operations and safety. Industrial labeling plays a pivotal role in achieving these goals. Effective labeling systems help employees quickly identify equipment, hazardous areas, and essential information, reducing errors and improving productivity. This blog will explore creative industrial labeling ideas that enhance workspace organization while ensuring safety and efficiency.

Introduction: The Importance of Industrial Labeling

Industrial labeling is more than just placing stickers on equipment or containers. It’s about creating an organized and efficient workspace where information is easily accessible, and safety protocols are communicated. Proper labeling can prevent accidents, improve workflow, and ensure that the necessary equipment is in the right place at the right time. By following creative labeling strategies, businesses can enhance safety, boost productivity, and streamline operations.

Benefits of Proper Labeling in Industrial Workspaces

Proper labeling offers several benefits in industrial environments:

- Enhanced Safety: Labels can warn of hazards, direct employees to safety equipment, and highlight areas that require caution.

- Improved Organization: Labeling ensures tools, machinery, and storage areas are easily identifiable, reducing time spent searching for items.

- Compliance with Regulations: Labeling helps meet regulatory requirements, ensuring that safety standards are followed.

- Increased Efficiency: Clear labels on inventory or workstations streamline tasks, reducing confusion and enhancing workflow.

Types of Labels for Industrial Use

When it comes to industrial labeling, choosing the right type of label is essential. Here are some common types of labels used in industrial settings:

Durable Labels

Durability is key in industrial environments, where labels are exposed to harsh conditions like moisture, heat, or abrasion. Durable labels made from materials like vinyl or polyester are resistant to wear and tear, ensuring they last longer and maintain legibility.

Color-Coded Labels

Color coding simplifies identification. Color-coded labels help workers quickly distinguish between different categories of tools, equipment, or storage. For example, blue labels might indicate electrical tools, while red labels could highlight hazardous chemicals.

Barcode Labels

Barcode labels are an excellent way to track inventory, equipment, and machinery. By scanning the barcode, employees can quickly access vital information such as maintenance schedules, inventory counts, or safety data sheets.

Creative Labeling Ideas to Enhance Organization

Industrial labeling can be both functional and creative. Here are some ideas to improve workspace organization:

Floor Labeling for Clear Pathways

In large industrial spaces, it’s essential to have clearly marked paths for movement. Floor labeling can help define walkways, ensure equipment is stored in designated areas, and guide workers to key locations like emergency exits. Using bold, highly visible labels on floors can prevent accidents and keep workflows uninterrupted.

Color-Coding for Easy Identification

Color coding is a powerful tool in any industrial labeling system. By associating colors with specific categories (e.g., blue for electrical equipment, red for emergency exits), workers can quickly identify what they need. This system reduces errors and saves valuable time, especially in fast-paced environments.

Custom Labels for Specific Equipment

Every workspace is unique, and so are the tools and machinery used within it. Custom safety labels can be designed for each piece of equipment, providing clear instructions or maintenance information. For example, labels on machinery can indicate operating guidelines or scheduled inspection dates, keeping everything running smoothly.

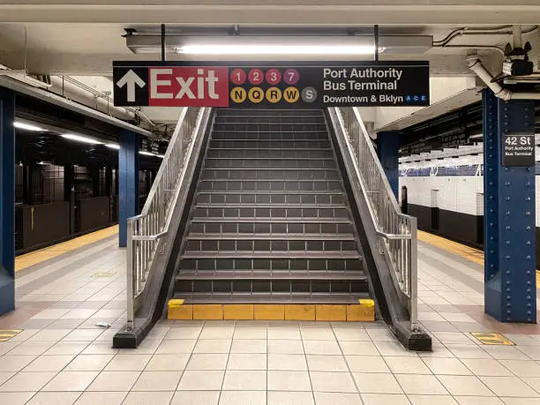

Effective Label Placement: Where to Put Your Labels

Label placement is as important as the labels themselves. Properly placed labels ensure that the right information is available at the right time. Here are some effective placement tips:

High-Traffic Areas

In areas with heavy foot traffic or machinery use, it’s essential to place labels in highly visible locations. For example, safety labels on machines or walls should be placed at eye level or near key entry points to ensure they are immediately noticeable.

Shelves and Storage Areas

Clear labels on shelves and storage bins help workers quickly find what they need. Shelf labels should include both the contents and any necessary handling instructions. For hazardous materials, make sure the labels are bold and easy to read from a distance.

Machinery and Equipment Labels

Every piece of machinery should have its own equipment label that includes operational instructions, safety warnings, and maintenance schedules. This helps operators use equipment safely and understand its condition without having to consult manuals.

Best Practices for Labeling Industrial Equipment

To create a functional and reliable labeling system, follow these best practices:

- Clear and Consistent Messaging: Labels should convey information in simple, direct terms. Use clear fonts and bold text to make messages stand out. Avoid jargon that could confuse employees.

- Using Labels for Safety Protocols: Safety-related labels should be placed near equipment, machinery, or hazardous materials. They should contain clear warning symbols, such as caution, danger, or warning, to alert employees to specific risks.

- Choosing The right Lable Materials:Labels should be made of materials suited for the environment. Use weatherproof, scratch-resistant materials for outdoor labeling or in high-abrasion areas. Choose adhesive labels that won’t peel off easily.

How to Maintain and Update Your Labeling System

A labeling system is not static; it needs regular maintenance and updates. Ensure that labels remain legible and intact over time. Here’s how:

- Inspect Regularly: Make periodic checks to ensure that labels are not fading, peeling, or damaged. Replace worn-out labels promptly.

- Update Information: As equipment changes or safety protocols evolve, update the labels to reflect the latest information. This is crucial for compliance and safety.

- Clean Labels: Ensure labels are clean and not obstructed by dirt or debris. A clear, visible label is far more effective in communicating important information.

Technology and Automation in Industrial Labeling

With advancements in technology, industrial labeling is becoming more efficient and precise. Here are some examples of how technology can improve labeling:

QR Code and RFID Labels

QR code labels and RFID tags can provide quick access to detailed information about equipment, tools, or inventory. By scanning the code, workers can access real-time data, maintenance schedules, and even troubleshooting guides.

Digital Labeling Systems

Digital systems allow for easy design, printing, and tracking of labels. With digital labeling systems, businesses can create custom labels, integrate them into their inventory management systems, and update them as needed, all from one platform.

Labeling Compliance: Meeting Safety Standards

In addition to organizing workspaces, labeling plays a key role in maintaining labeling compliance with industry regulations. For example, OSHA (Occupational Safety and Health Administration) requires workplaces to have clear and visible labels indicating hazards and safety protocols. This ensures that companies meet legal safety requirements and minimize liability.

Top Safety Tag Ideas to Improve Workplace Safety

|

Safety Tags |

Short Description |

|

Explore creative safety tag ideas that can help improve safety communication and compliance in the workplace. |

|

|

Learn effective floor marking ideas to organize workspaces, improve traffic flow, and enhance safety in various environments. |

|

|

Discover warehouse safety ideas that help reduce risks, improve operations, and create a safer working environment. |

|

|

Check out innovative workplace safety tag ideas designed to improve hazard communication and reduce workplace injuries. |

|

|

A comprehensive guide to safety signage ideas that enhance visibility, promote safety awareness, and meet regulatory standards. |

|

|

Get ideas for industrial labeling that ensures proper hazard identification, equipment safety, and regulatory compliance. |

|

|

Explore the best safety tag ideas specifically designed for factories to improve safety measures and operational efficiency. |

Conclusion

Industrial labeling isn’t just about marking items; it’s about creating an organized, efficient, and safe environment. By using creative labeling ideas, businesses can improve workflow, enhance safety, and comply with industry standards. Whether through custom safety labels or color-coded labeling systems, effective labeling ensures that everyone in the workplace has access to the right information at the right time.

For more information on industrial labeling and workplace organization tips, visit our Industrial Labeling Solutions page.

Frequently Asked Questions (FAQs)

What is the best material for industrial labels?

Durable materials such as vinyl, polyester, or laminated materials are ideal for industrial environments because they can withstand harsh conditions.

How can color-coded labels improve warehouse efficiency?

Color-coded labels allow workers to quickly identify items based on categories, reducing time spent searching for equipment and improving workflow.

Are QR code labels effective in industrial settings?

Yes, QR code labels provide quick access to detailed information about equipment, maintenance schedules, and safety protocols, improving efficiency.

Where should I place safety labels in my workplace?

Safety labels should be placed in high-traffic areas, on machinery, and in storage zones to ensure they’re visible and accessible when needed.

How often should I update my labeling system?

Regular updates should be made whenever equipment, processes, or safety protocols change. It’s also important to check labels regularly for wear and tear.