Creative Floor Marking Ideas for Safety and Organization

Introduction: The Role of Floor Markings in Workplace Safety

Floor marking is an essential yet often overlooked aspect of workplace safety and organization. It helps guide employees, visitors, and equipment operators, reducing the risk of accidents and improving workflow efficiency. Whether in a factory, warehouse, hospital, or retail space, well-planned floor markings create a structured and safe environment.

Implementing safety zones enhances workplace safety by clearly designating hazards, pathways, and work areas. These visual cues improve communication and ensure compliance with safety regulations. In this blog, we will explore innovative warehouse marking solutions to improve workplace safety and organization

.

Understanding Different Types of Floor Markings

Color-Coded Floor Markings and Their Meanings

Color coding is one of the most effective ways to communicate important information through floor markings. Here are some standard colors and their meanings:

Yellow: Designates walkways, aisles, and traffic lanes.

Red: Indicates fire hazards, emergency stops, or danger zones.

Blue: Represents equipment or inspection areas.

Green: Marks safe zones or first-aid stations.

Black and White: Used for general information or organizational purposes.

Shapes and Symbols for Clear Communication

In addition to colors, workplaces can use symbols such as arrows, footprints, and stop signs to reinforce important messages. For example, footprints guide pedestrian flow, while arrows indicate traffic direction in warehouses.

Glow-in-the-Dark and Reflective Markings for Visibility

Glow-in-the-dark and reflective tapes are ideal for environments with low lighting, such as emergency exits or power outage-prone areas. These markings ensure visibility and safety even in poor lighting conditions.

Safety Applications of Floor Markings

Hazard Identification and Restricted Areas

Clearly marked safety zones help prevent workplace accidents. Markings around dangerous machinery, electrical panels, and hazardous material storage areas alert employees to potential risks.

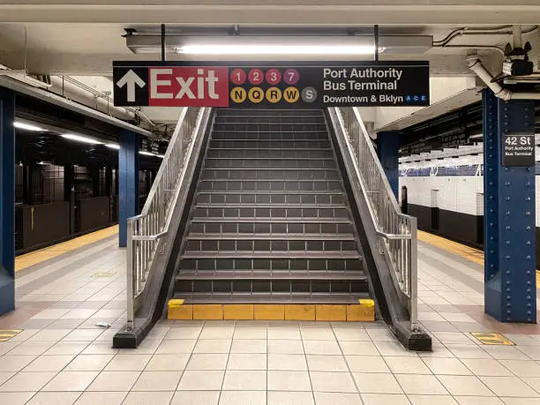

Pathways and Emergency Exit Routes

Floor markings should designate clear paths to emergency exits, helping employees evacuate safely in case of an emergency. Brightly colored or glow-in-the-dark pathways are particularly useful in high-risk environments.

Equipment and Machinery Safety Zones

Machinery and high-traffic equipment areas should have designated floor markings to keep workers safe. Marking buffer zones around machines ensures operators and pedestrians maintain a safe distance.

Floor Marking Strategies for Workplace Organization

Designating Work Zones and Storage Areas

Floor markings can separate work areas, ensuring employees know where different tasks take place. This prevents clutter and maintains an organized workspace. Storage areas should be clearly marked to avoid misplaced tools and materials.

Traffic Flow and Pedestrian Safety

Busy workplaces, especially warehouses and manufacturing facilities, must have defined traffic lanes for forklifts, pallet jacks, and pedestrians. Clear separation reduces the chances of accidents.

Implementing 5S Floor Marking for Lean Workspaces

The 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) focuses on workplace efficiency and organization. Floor markings play a vital role in this system by creating clearly labeled spaces for tools, equipment, and materials.

Innovative Floor Marking Ideas for Various Industries

Manufacturing and Warehousing Solutions

Zebra striping to indicate areas with heavy machinery movement.

Footprint markers to direct employees to workstations.

Loading dock outlines for efficient truck unloading.

Healthcare and Laboratory Markings

Isolation room boundaries for infection control.

Labeled biohazard zones for hazardous material safety.

Emergency response paths leading to critical care areas.

Retail and Public Space Applications

Checkout lane guides for smoother customer movement.

Social distancing markers for crowd management.

Restricted zones to prevent unauthorized access.

Choosing the Right Floor Marking Materials

Durable Tape vs. Paint: Pros and Cons

Tape: Easy to install and replace, but may wear out in high-traffic areas.

Paint: More durable but requires longer drying time and maintenance.

Anti-Slip and High-Traffic Solutions

For areas with frequent movement, anti-slip coatings and abrasive floor tapes provide additional grip, preventing slips and falls.

Removable vs. Permanent Markings

Temporary workplaces, such as construction sites, benefit from removable floor tape, while permanent facilities should use long-lasting paint or epoxy coatings.

How to Create an Effective Floor Marking System

Proper Planning and Layout Design

Before applying floor markings, businesses should conduct a safety assessment and create a layout that improves workflow and minimizes risks.

Employee Training and Awareness Programs

Employees should understand what different markings signify. Regular training ensures compliance with safety protocols.

Regular Maintenance and Updating of Markings

Workplaces should inspect floor markings periodically to ensure visibility and effectiveness. Worn-out markings should be replaced immediately.

Benefits of Floor Marking

Investing in floor marking solutions improves safety, enhances workflow, and promotes compliance with industry regulations. Some key advantages include:

Improved safety: Helps prevent accidents by clearly identifying hazards.

Better organization: Defines workspaces, storage areas, and pathways.

Enhanced efficiency: Reduces confusion and optimizes workflow.

Regulatory compliance: Helps businesses meet safety standards.

By implementing the right warehouse marking strategies, businesses can create a safer and more productive workspace for employees and visitors.

Explore More: Essential Safety Tips for Every Workplacy

|

Safety Tags |

Short Description |

|

Explore creative safety tag ideas that can help improve safety communication and compliance in the workplace. |

|

|

Learn effective floor marking ideas to organize workspaces, improve traffic flow, and enhance safety in various environments. |

|

|

Discover warehouse safety ideas that help reduce risks, improve operations, and create a safer working environment. |

|

|

Check out innovative workplace safety tag ideas designed to improve hazard communication and reduce workplace injuries. |

|

|

A comprehensive guide to safety signage ideas that enhance visibility, promote safety awareness, and meet regulatory standards. |

|

|

Get ideas for industrial labeling that ensures proper hazard identification, equipment safety, and regulatory compliance. |

|

|

Explore the best safety tag ideas specifically designed for factories to improve safety measures and operational efficiency. |

Conclusion

A well-planned floor marking system is a crucial part of workplace safety and organization. It helps define spaces, improve workflow, and ensure compliance with industry regulations.

If you're looking for high-quality floor marking solutions, check out Archford for a variety of workplace safety products.

FAQs:

1. What are the standard colors used for floor markings in workplaces?

Standard colors include yellow for walkways, red for danger zones, blue for equipment areas, and green for safe zones.

2. How do floor markings improve workplace safety?

They guide employees, highlight hazards, and create designated areas to prevent accidents.

3. Can floor markings be customized for specific business needs?

Yes, businesses can use custom safety labels with colors, symbols, and text to fit their unique safety requirements.

4. How often should floor markings be maintained or replaced?

Markings should be inspected regularly and replaced when they begin to fade or wear out.

5. Are there regulations governing workplace floor markings?

Yes, organizations like OSHA provide guidelines on how to create an effective floor marking system to ensure workplace safety compliance.