Mine Safety Guides: Reducing Workplace Hazards

Introduction to Mine Safety

Mining is a high-risk industry where safety is a top priority. The hazards in mining environments can lead to severe injuries or fatalities if proper precautions are not followed. Implementing strict mine safety measures is essential to protect workers and ensure efficient operations.

Following Mine Safety Guides helps in minimizing risks, improving compliance, and enhancing overall workplace safety. Companies like Archford provide high-quality resources to help mining professionals adopt best safety practices and comply with industry regulations.

The Importance of Mine Safety Guides

Safety in mining goes beyond preventing accidents—it’s about creating a culture of protection and efficiency. By following comprehensive safety guides, mining companies can:

-

Reduce workplace injuries and fatalities

-

Comply with government regulations

-

Improve worker confidence and productivity

-

Minimize operational losses from accidents

A Mine Safety Guide provides essential information on handling risks, using protective gear, and responding effectively to emergencies.

Common Hazards in Mining Environments

Mining presents numerous hazards that can compromise worker safety. Some of the most common risks include:

1. Cave-ins and Rockfalls

One of the most severe threats in underground mines is structural collapse. Proper support systems and safety inspections are essential for mining hazard prevention.

2. Exposure to Toxic Gases

Hazardous gases like carbon monoxide, methane, and silica dust pose serious health risks. Proper ventilation systems and gas detection equipment are necessary to prevent underground mining risks.

3. Heavy Machinery Accidents

Improper handling of mining equipment can cause fatal accidents. Workers should undergo proper training and follow strict operational guidelines.

4. Explosions and Fires

Flammable gases and improper use of explosives increase fire hazards. Proper storage, handling, and safety procedures must be enforced.

5. Ergonomic and Physical Strain

Miners are exposed to repetitive tasks and heavy lifting, which can lead to long-term musculoskeletal injuries. Workplace safety in mining should include ergonomic measures to reduce physical stress.

Essential Safety Measures for Miners

1. Implementing Safety Inspections

Regular safety inspections identify potential hazards before they cause harm. Routine checks ensure that equipment, structures, and protective gear are in proper condition.

2. Proper Training and Education

Safety training is essential to prepare miners for emergency situations and equip them with the knowledge to handle risks effectively. Workers should be trained on:

-

Safe equipment operation

-

Emergency response procedures

-

Hazard recognition

A well-trained workforce significantly reduces the chances of accidents and injuries.

3. Using Personal Protective Equipment (PPE)

Wearing the right PPE for miners is crucial to ensuring safety in hazardous environments. Essential protective equipment includes:

-

Hard hats – Protection against falling debris.

-

Respirators and masks – Prevent inhalation of toxic dust and gases.

-

Safety harnesses – Reduce fall risks in elevated work areas.

-

Steel-toe boots and gloves – Protect against sharp objects and heavy machinery.

Companies like Archford offer high-quality safety gear and protective equipment to enhance workplace safety in mining.

Emergency Preparedness and Response

Even with strict safety measures, accidents can still occur. A well-developed emergency response plan is essential for:

-

Evacuating workers quickly and safely

-

Providing immediate first aid

-

Containing hazardous situations

Conducting regular emergency drills ensures that workers are prepared to respond effectively in case of an incident.

Technology and Innovation in Mine Safety

Advancements in mining safety technology have significantly improved risk management. Some key innovations include:

Automated gas detection systems – Monitor air quality and detect dangerous gas leaks.

Drones for site inspections – Minimize worker exposure to hazardous environments.

Wearable safety devices – Monitor worker health and alert them to potential hazards.

AI-driven safety analytics – Predict potential risks and prevent accidents before they occur.

These technologies enhance workplace safety and help mining companies maintain regulatory compliance in mining.

Regulatory Compliance and Legal Obligations

Mining companies must follow strict regulations to protect workers and the environment. Compliance with government safety laws includes:

-

Adhering to workplace safety standards

-

Providing proper safety equipment

-

Conducting regular safety inspections and audits

-

Maintaining environmental safety measures

Failure to meet regulatory compliance in mining can lead to severe penalties and legal action.

How Archford Supports Mine Safety

Archford is committed to improving safety in the mining industry. They offer high-quality safety solutions and resources, including:

-

Comprehensive Mine Safety Guide

-

Protective equipment and PPE for miners

-

Educational materials for mining safety training

-

Innovative safety tools to reduce workplace hazards

By utilizing Archford's safety products, mining companies can create a safer, more efficient work environment.

The Ultimate Guide to Workplace Safety: Best Practices for Every Industry

|

Safety Guide |

Tips |

|

Implement Sort, Set in Order, Shine, Standardize, and Sustain for workplace efficiency. |

|

|

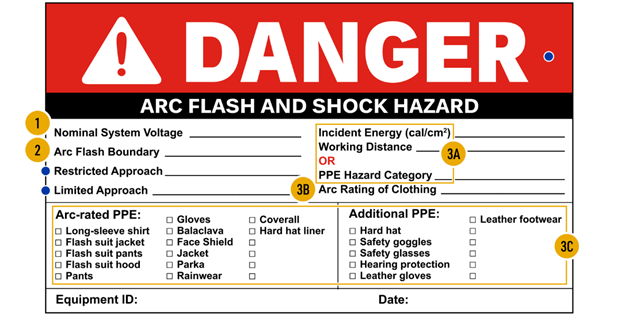

Use proper labels with voltage ratings, approach boundaries, and PPE requirements to ensure electrical safety. |

|

|

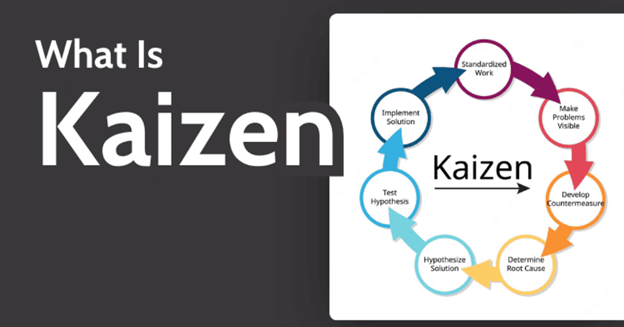

Apply lean methodologies like Kaizen and Six Sigma to enhance operational efficiency. |

|

|

Ensure all hazardous materials are labeled with correct pictograms, signal words, and hazard statements. |

|

|

Use proper lockout devices and tags to prevent accidental energy releases during maintenance. |

|

|

Follow standard color codes and label pipes at regular intervals for easy identification. |

|

|

Place warning signs in high-risk areas to comply with OSHA standards and improve workplace safety. |

|

|

Use AS 1345 standard colors and labels for accurate pipe identification in Australian industries. |

|

|

Add ‘Safety’ to the 5S system to further enhance workplace organization and hazard prevention. |

|

|

Use different colors for specific zones—e.g., red for fire hazards, yellow for caution, and green for safety paths. |

|

|

Encourage small, continuous improvements by involving employees in process optimization. |

|

|

Use visual signals to manage workflow and reduce inefficiencies in production. |

|

|

Implement proper PPE, ventilation, and emergency procedures to ensure worker safety in mining operations. |

|

|

Use durable, heat-resistant labels to prevent misidentification of electrical wiring. |

|

|

Maintain clear aisles, proper signage, and forklift safety measures to reduce accidents. |

|

|

Optimize layout, use barcode scanning, and implement inventory tracking systems for smooth operations. |

|

|

Use consistent signage, color-coded paths, and lighting to improve navigation. |

|

|

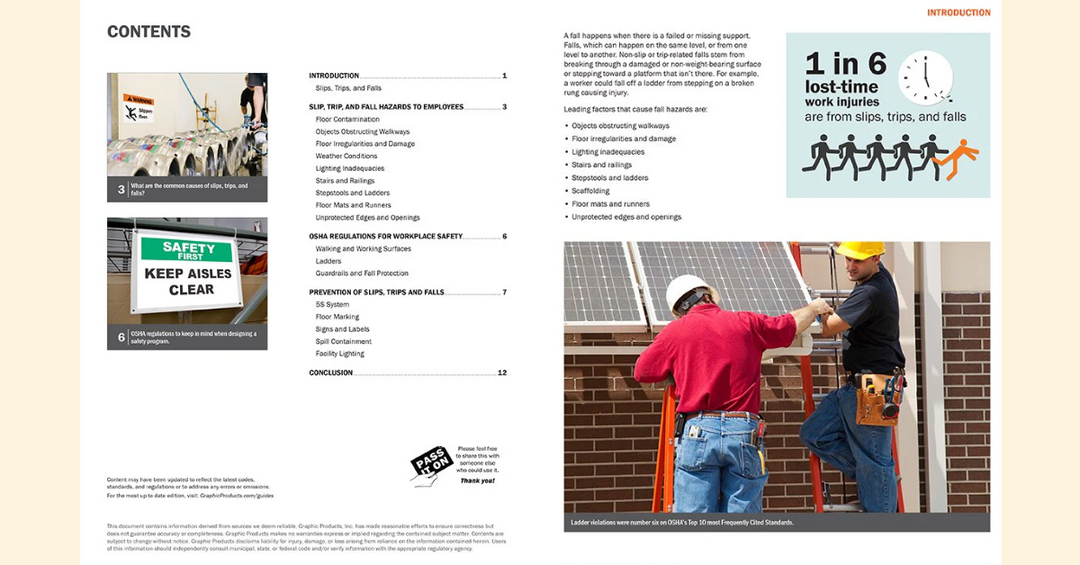

Keep floors dry, use anti-slip mats, and mark hazard areas to prevent workplace injuries. |

|

|

Use labels, floor markings, and visual boards to improve communication and organization. |

|

|

Clearly label valves with durable tags to ensure safe and proper operation. |

Conclusion

Mine safety is essential for protecting workers and ensuring smooth operations. By following mine safety guides, using proper protective equipment, and adopting modern safety technologies, mining companies can reduce risks and improve compliance.

With trusted resources from Archford, mining professionals can stay up to date with safety standards and regulations. Prioritizing safety leads to fewer accidents, higher productivity, and a better working environment.

Frequently Asked Questions (FAQs)

1. What are the main safety risks in mining?

Common risks include cave-ins, toxic gas exposure, machinery accidents, fires, and ergonomic injuries.

2. How can mining companies prevent accidents?

Mining companies can enhance safety by conducting regular inspections, providing safety training, and equipping workers with PPE.

3. What is the role of PPE in mining safety?

PPE for miners helps protect against physical injuries, toxic gas exposure, and environmental hazards. Essential PPE includes hard hats, gloves, respirators, and safety harnesses.

4. Why is emergency preparedness important in mining?

A well-prepared emergency response plan helps evacuate workers quickly and minimize damage during accidents or disasters.

5. How can technology improve mine safety?

Innovations like automated gas detection, drones for inspections, wearable safety devices, and AI-driven analytics help predict and prevent workplace hazards.