Preventing Slips, Trips & Falls Guide: Workplace Safety

Introduction

Workplace safety is essential for protecting employees from injuries and ensuring business operations run smoothly. Among the most common workplace accidents are slips, trips, and falls, which can result in serious injuries, lost productivity, and legal liability.

At Archford, we prioritize workplace hazard reduction by offering high-quality safety solutions, including signage, floor markings, and workplace safety guides.

In this Preventing Slips, Trips & Falls Guide, we’ll cover common hazards, prevention strategies, and regulatory compliance to help you create a safer work environment.

Understanding Slips, Trips, and Falls

Common Causes of Workplace Accidents

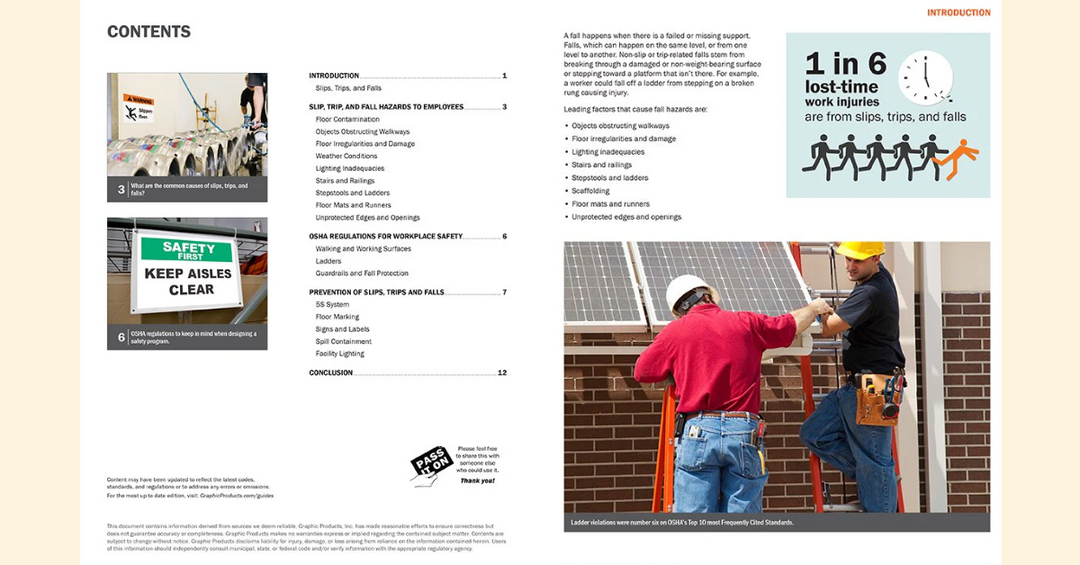

Several factors contribute to slips, trips, and falls in the workplace, including:

-

Slippery floors from spills, cleaning, or moisture buildup.

-

Uneven surfaces, such as cracked flooring or loose carpets.

-

Poor lighting, making it difficult to spot hazards.

-

Cluttered walkways with cables, tools, or other obstacles.

-

Inappropriate footwear, leading to a lack of grip and stability.

Industries Most at Risk

Some industries face a higher risk of falls due to their work environments, including:

-

Construction – Uneven terrain, scaffolding, and open heights create hazards.

-

Warehousing and logistics – Workers deal with slippery floors, stacked inventory, and moving equipment.

-

Healthcare – Spills, rushing employees, and patient care environments increase risks.

-

Hospitality and retail – High foot traffic and polished floors contribute to frequent incidents.

Identifying Hazardous Areas

High-Risk Zones in the Workplace

Certain areas in workplaces require extra safety measures:

-

Entrances and exits – Exposure to rain and moisture makes these areas slippery.

-

Stairwells – Poor lighting, missing handrails, or uneven steps increase fall risks.

-

Storage rooms – Cluttered areas create tripping hazards.

-

Kitchens and break rooms – Frequent spills make these areas high-risk.

How to Conduct a Workplace Safety Assessment

A thorough workplace hazard reduction assessment involves:

-

Identifying hazards in different areas of the workplace.

-

Inspecting flooring conditions for cracks, spills, or loose materials.

-

Evaluating lighting levels to ensure visibility.

-

Implementing proper housekeeping practices to eliminate clutter.

-

Training employees to recognize and report hazards.

Best Practices for Preventing Slips, Trips, and Falls

Implementing Fall Prevention Strategies

A proactive approach to fall prevention strategies includes:

-

Regular maintenance of floors, walkways, and staircases.

-

Installing handrails in areas with elevation changes.

-

Using warning signs for wet floors and uneven surfaces.

-

Training employees on hazard recognition and response.

Enhancing Floor Safety Measures

Investing in proper floor safety measures can significantly reduce fall risks:

-

Non-slip coatings for floors in high-traffic areas.

-

Anti-slip mats in entryways, kitchens, and bathrooms.

-

Clearly marked walkways with floor markings and hazard signs.

-

Regular inspections to identify worn-out flooring or hazards.

Ensuring OSHA Slip Resistance Compliance

Businesses must comply with OSHA slip resistance standards to prevent workplace injuries. OSHA regulations require:

-

Slip-resistant flooring materials in high-risk areas.

-

Proper signage and hazard warnings in wet or slippery zones.

-

Fall protection training for employees working in elevated locations.

Failure to comply with OSHA safety standards can result in fines and legal consequences.

Essential Safety Equipment for Workplaces

Anti-Slip Mats and Floor Markings

Anti-slip mats help provide traction in slippery areas, reducing fall risks. Additionally, high-visibility floor markings help workers navigate safely.

Footwear for Maximum Grip and Safety

Wearing proper footwear is an essential part of injury prevention tips. Employees should use:

-

Slip-resistant shoes with rubber soles.

-

Water-resistant materials for wet environments.

-

Steel-toe boots for industrial workplaces.

Proper Signage and Hazard Warnings

-

Wet floor signs should always be used after cleaning.

-

Directional signage can guide employees safely through workspaces.

-

High-contrast hazard markings help identify dangerous areas.

Emergency Preparedness and Response

Developing an Effective Emergency Plan

A well-structured emergency plan ensures that employees respond effectively to accidents. This plan should include:

-

Designated safety officers to oversee emergency responses.

-

Clearly posted emergency contact information.

-

Regular safety drills to keep employees prepared.

Training Employees for Quick Response

Employees should know how to:

-

Assist injured colleagues without causing further harm.

-

Report workplace accidents immediately.

-

Follow evacuation procedures when necessary.

Archford’s Commitment to Workplace Safety

At Archford, we provide top-tier safety solutions to help businesses maintain a secure work environment. Our Preventing Slips, Trips & Falls Guide offers:

-

Safety signage and floor marking solutions.

-

Hazard assessment tools to prevent workplace falls.

-

Customized safety solutions for different industries.

For expert workplace safety products and guides, visit Archford today!

The Ultimate Guide to Workplace Safety: Best Practices for Every Industry

|

Safety Guide |

Tips |

|

Implement Sort, Set in Order, Shine, Standardize, and Sustain for workplace efficiency. |

|

|

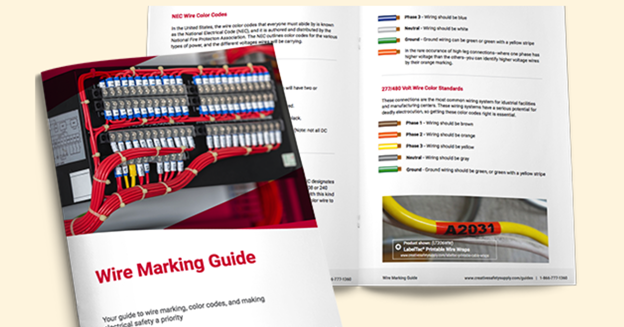

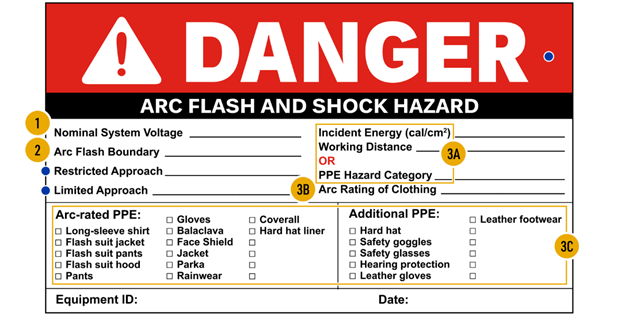

Use proper labels with voltage ratings, approach boundaries, and PPE requirements to ensure electrical safety. |

|

|

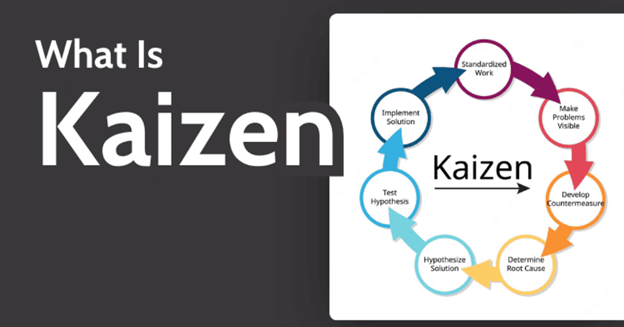

Apply lean methodologies like Kaizen and Six Sigma to enhance operational efficiency. |

|

|

Ensure all hazardous materials are labeled with correct pictograms, signal words, and hazard statements. |

|

|

Use proper lockout devices and tags to prevent accidental energy releases during maintenance. |

|

|

Follow standard color codes and label pipes at regular intervals for easy identification. |

|

|

Place warning signs in high-risk areas to comply with OSHA standards and improve workplace safety. |

|

|

Use AS 1345 standard colors and labels for accurate pipe identification in Australian industries. |

|

|

Add ‘Safety’ to the 5S system to further enhance workplace organization and hazard prevention. |

|

|

Use different colors for specific zones—e.g., red for fire hazards, yellow for caution, and green for safety paths. |

|

|

Encourage small, continuous improvements by involving employees in process optimization. |

|

|

Use visual signals to manage workflow and reduce inefficiencies in production. |

|

|

Implement proper PPE, ventilation, and emergency procedures to ensure worker safety in mining operations. |

|

|

Use durable, heat-resistant labels to prevent misidentification of electrical wiring. |

|

|

Maintain clear aisles, proper signage, and forklift safety measures to reduce accidents. |

|

|

Optimize layout, use barcode scanning, and implement inventory tracking systems for smooth operations. |

|

|

Use consistent signage, color-coded paths, and lighting to improve navigation. |

|

|

Keep floors dry, use anti-slip mats, and mark hazard areas to prevent workplace injuries. |

|

|

Use labels, floor markings, and visual boards to improve communication and organization. |

|

|

Clearly label valves with durable tags to ensure safe and proper operation. |

Conclusion

Preventing slips, trips, and falls requires proactive hazard management, compliance with OSHA safety standards, and investment in proper safety equipment. By following injury prevention tips, businesses can reduce accidents, protect employees, and improve workplace safety.

Frequently Asked Questions (FAQs)

1. What are the most effective fall prevention strategies?

The best strategies include maintaining clean floors, using anti-slip mats, ensuring proper lighting, and training employees on hazard recognition.

2. How can I ensure my workplace complies with OSHA slip resistance standards?

Compliance requires using slip-resistant flooring, posting hazard signs, and providing employee training on fall prevention.

3. What role does footwear play in reducing workplace falls?

Proper footwear provides better grip, stability, and protection, reducing the risk of slips and falls.

4. How often should businesses inspect their floors for safety?

Regular floor safety measures include daily visual checks and monthly in-depth inspections to identify potential hazards.

5. Where can I find high-quality workplace safety solutions?

Archford offers signage, floor markings, and safety solutions to enhance workplace safety and reduce accident risks.