Comprehensive Valve Tagging Guide for Industrial Safety

Introduction to Valve Tagging

In industrial environments, valve tagging is a vital safety measure that ensures clear identification of pipelines, valves, and flow systems. By implementing a well-structured valve tagging system, industries can enhance safety, efficiency, and regulatory compliance while reducing the risk of operational errors.

At Archford, we provide high-quality valve tagging solutions to help businesses streamline their pipe and valve management. Our Valve Tagging Guide offers essential insights into best practices, industry standards, and compliance requirements.

Why Valve Tagging is Essential for Industrial Safety

Valve tagging is a critical component of process safety compliance, helping organizations:

-

Improve workplace safety – Clear labels prevent misoperations and hazardous incidents

-

Enhance operational efficiency – Proper tagging speeds up maintenance, troubleshooting, and emergency response.

-

Meet regulatory requirements – Organizations must comply with safety regulations such as ANSI and OSHA.

-

Prevent costly mistakes – Proper labeling reduces the risk of accidental spills, shutdowns, or equipment damage.

By implementing a standardized tagging system, industries can ensure safe and efficient operations while maintaining compliance with safety protocols.

Types of Valve Tags and Their Applications

Industrial settings require different types of valve tags depending on the environment, durability needs, and compliance requirements.

1. Plastic Valve Tags

-

Lightweight, cost-effective, and ideal for indoor environments

-

Best for applications where corrosion is not a major concern

2. Stainless Steel Valve Tags

-

Highly durable and corrosion-resistant

-

Used in chemical plants, marine environments, and refineries

3. Brass Valve Tags

-

Withstands high temperatures and harsh conditions

-

Commonly found in boiler rooms and industrial piping systems

4. ANSI Valve Tags

-

Designed to meet American National Standards Institute (ANSI) safety regulations

-

Used in industries where standardized labeling is required for compliance

Selecting the right tag ensures clear identification, long-term readability, and compliance with safety regulations.

Best Practices for Valve Safety Labeling

To maintain a safe and efficient industrial workspace, it’s crucial to follow best practices for valve safety labeling:

Use clear and standardized labeling – Tags should include identification numbers, flow direction, and hazard warnings.

Color-code valve tags – Helps workers quickly identify valve functions and fluid types.

Use durable materials – Tags should withstand extreme temperatures, chemicals, and environmental exposure.

Ensure regular maintenance – Replace damaged or faded tags to maintain visibility.

Train employees on valve identification – Workers should understand the tagging system to avoid operational errors.

Following these best practices reduces workplace hazards and improves efficiency.

How to Implement an Effective Valve Tagging System

Setting up a valve tagging system involves multiple steps to ensure maximum efficiency and compliance:

-

Conduct a Valve Audit – Identify all critical valves that require tagging.

-

Select the Appropriate Tags – Choose from stainless steel, plastic, or ANSI-compliant tags based on environmental conditions.

-

Standardize Labeling Information – Include valve numbers, function, pressure ratings, and flow direction.

-

Train Staff on Identification Procedures – Workers should understand the importance of industrial valve identification.

-

Schedule Regular Inspections – Periodic tag maintenance ensures compliance and operational efficiency.

By following these steps, businesses can enhance workplace safety and ensure compliance with industry standards.

Regulatory Compliance and Industry Standards for Valve Tagging

Many industries must comply with national and international safety standards regarding valve tagging. These include:

OSHA (Occupational Safety and Health Administration) – Requires proper valve labeling to reduce workplace hazards.

ANSI (American National Standards Institute) – Establishes guidelines for standardized labeling and color codes.

ISO 14726 – Defines identification colors for pipelines and valves in industrial settings.

NFPA (National Fire Protection Association) – Ensures proper identification of fire suppression system valves.

Using ANSI valve tags ensures businesses remain compliant with safety regulations while improving efficiency.

Common Mistakes to Avoid in Valve Tagging

While valve tagging is a simple but crucial process, many industries make common errors that can compromise safety:

Using low-quality tags that fade, break, or become illegible.

Failing to update tags when system modifications occur.

Overlooking compliance requirements, leading to regulatory penalties.

Lack of employee training, resulting in misinterpretation of valve functions.

Avoiding these mistakes ensures workplace safety, efficiency, and regulatory adherence.

How Valve Tagging Enhances Workplace Efficiency

A well-organized valve tagging system not only improves safety but also enhances workplace efficiency by:

Reducing downtime – Workers can quickly locate specific valves during maintenance or emergencies.

Streamlining operations – Proper tagging allows for efficient workflow management.

Enhancing safety training – Employees can easily learn industrial valve identification protocols.

By implementing a structured valve tagging system, businesses can increase productivity and operational safety.

Choosing the Right Valve Tagging Solutions

When selecting a valve tagging system, consider:

Durability and resistance to environmental factors

Compliance with OSHA, ANSI, and industry-specific regulations

Customization options for industry-specific applications

At Archford, we offer high-quality tagging solutions to help businesses meet safety and compliance requirements. Our Valve Tagging Guide provides expert insights on effective valve labeling and identification systems.

The Ultimate Guide to Workplace Safety: Best Practices for Every Industry

|

Safety Guide |

Tips |

|

Implement Sort, Set in Order, Shine, Standardize, and Sustain for workplace efficiency. |

|

|

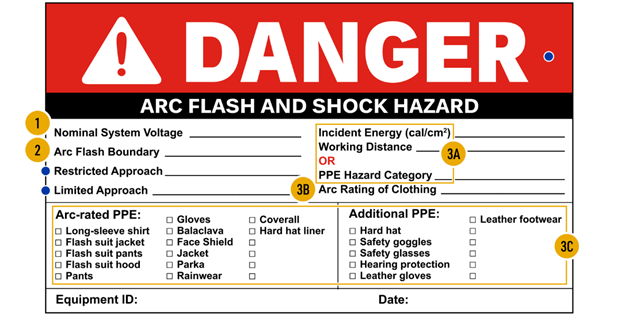

Use proper labels with voltage ratings, approach boundaries, and PPE requirements to ensure electrical safety. |

|

|

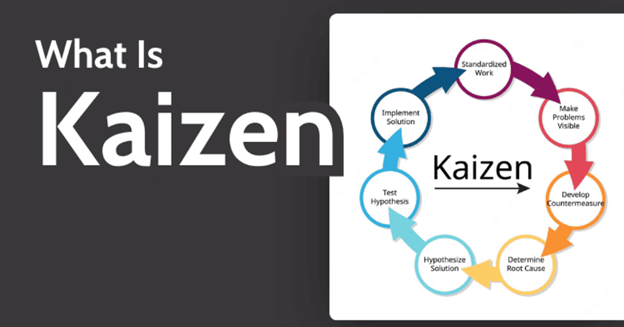

Apply lean methodologies like Kaizen and Six Sigma to enhance operational efficiency. |

|

|

Ensure all hazardous materials are labeled with correct pictograms, signal words, and hazard statements. |

|

|

Use proper lockout devices and tags to prevent accidental energy releases during maintenance. |

|

|

Follow standard color codes and label pipes at regular intervals for easy identification. |

|

|

Place warning signs in high-risk areas to comply with OSHA standards and improve workplace safety. |

|

|

Use AS 1345 standard colors and labels for accurate pipe identification in Australian industries. |

|

|

Add ‘Safety’ to the 5S system to further enhance workplace organization and hazard prevention. |

|

|

Use different colors for specific zones—e.g., red for fire hazards, yellow for caution, and green for safety paths. |

|

|

Encourage small, continuous improvements by involving employees in process optimization. |

|

|

Use visual signals to manage workflow and reduce inefficiencies in production. |

|

|

Implement proper PPE, ventilation, and emergency procedures to ensure worker safety in mining operations. |

|

|

Use durable, heat-resistant labels to prevent misidentification of electrical wiring. |

|

|

Maintain clear aisles, proper signage, and forklift safety measures to reduce accidents. |

|

|

Optimize layout, use barcode scanning, and implement inventory tracking systems for smooth operations. |

|

|

Use consistent signage, color-coded paths, and lighting to improve navigation. |

|

|

Keep floors dry, use anti-slip mats, and mark hazard areas to prevent workplace injuries. |

|

|

Use labels, floor markings, and visual boards to improve communication and organization. |

|

|

Clearly label valves with durable tags to ensure safe and proper operation. |

Conclusion![]()

As industries continue to prioritize safety and efficiency, valve tagging will evolve with new technologies such as RFID-enabled tags and digital tracking systems. These advancements will enhance traceability, compliance, and workplace safety.

Investing in a robust valve tagging system ensures long-term efficiency, regulatory adherence, and accident prevention.

FAQs About Valve Tagging

1. What is valve tagging?

Valve tagging involves labeling industrial valves to ensure proper identification, enhance safety, and meet compliance standards.

2. Why is industrial valve identification important?

Proper industrial valve identification prevents misoperations, enhances maintenance efficiency, and ensures compliance with safety regulations.

3. What materials are best for valve tags?

Common materials include stainless steel, brass, anodized aluminum, and plastic, depending on environmental conditions and industry requirements.

4. How often should valve tags be replaced?

Tags should be inspected annually and replaced if they become faded, damaged, or outdated.

5. Where can I find high-quality valve tags?

At Archford, we provide premium valve tagging solutions that meet ANSI, OSHA, and industry standards for safety and efficiency.