Essential Wire and Cable Marking Guide for Safety

Introduction to Wire and Cable Marking

Proper wire and cable marking is a critical aspect of electrical cable safety in industries such as construction, manufacturing, and telecommunications. Clearly labeled cables help prevent hazards, miswiring, and costly downtime.

At Archford, high-quality cable identification tags and labeling solutions ensure compliance with industry standards and regulatory requirements. Whether you’re managing a complex electrical system or a data center, proper marking helps improve organization and workplace safety.

Why Proper Cable Marking Matters

Unmarked or incorrectly labeled wires can lead to:

Safety Hazards – Reduces the risk of electrical shocks, fires, and miswiring.

Regulatory Compliance – Ensures adherence to OSHA cable marking and safety regulations.

Efficient Troubleshooting – Helps technicians quickly identify and repair faults.

Operational Efficiency – Prevents downtime caused by misidentified wires.

By following wire coding standards and using the right labeling techniques, businesses can minimize risks and improve workflow efficiency.

Types of Wire and Cable Marking Solutions

Different industrial wire labeling solutions are available based on durability, environment, and industry requirements.

1. Printed Cable Labels

Pre-printed or custom labels provide quick and clear identification of cables. They are commonly used in:

-

Electrical panels

-

Data centers

-

Manufacturing plants

2. Heat Shrink Tubing

Printed tubing shrinks when heated, forming a permanent and durable label. It offers:

-

Resistance to moisture and chemicals

-

Long-lasting identification

-

Enhanced electrical cable safety

3. Engraved Tags and Wrap-Around Markers

These are ideal for outdoor applications or areas where cables are exposed to extreme conditions.

Selecting the right marking solution depends on industry regulations, environmental conditions, and labeling durability.

Best Practices for Wire and Cable Identification

To maximize the effectiveness of your wire and cable marking system, follow these best practices:

Use Standardized Labels – Follow wire coding standards for consistency.

Ensure Label Durability – Select materials that resist heat, chemicals, and environmental damage.

Keep Labels Legible – Use bold fonts and high-contrast colors for visibility.

Strategic Label Placement – Ensure markings are easily accessible for maintenance teams.

Regularly Inspect and Update Labels – Replace worn-out cable identification tags.

By following these guidelines, businesses can improve safety and efficiency.

Industry Standards for Cable Marking

Proper wire marking must comply with regulatory requirements to ensure safety and efficiency. Key standards include:

OSHA Cable Marking – Outlines workplace safety regulations for electrical wiring.

IEC 60445 – International standards for wire color coding.

ANSI/TIA-606-C – Guidelines for telecommunications cabling systems.

ISO/IEC 11801 – Standards for structured cabling in commercial buildings.

By ensuring compliance with these wire coding standards, companies reduce risks and maintain regulatory adherence.

Common Mistakes to Avoid in Cable Marking

Even with the best industrial wire labeling solutions, mistakes can still happen. Avoid these common errors:

Using Non-Durable Labels – Low-quality labels fade, smudge, or peel over time.

Inconsistent Labeling Methods – Mixing different labeling styles leads to confusion.

Ignoring Regulatory Compliance – Not following OSHA cable marking rules can result in penalties.

Overcomplicating Labeling – Labels should be clear, concise, and easy to understand.

Following standardized labeling practices ensures workplace safety and efficiency.

How Wire Marking Enhances Workplace Safety

Proper wire and cable marking is essential for workplace safety, helping businesses:

Prevent Electrical Accidents – Reduces risks of electric shock and fire hazards.

Ensure Compliance – Meets OSHA cable marking and industry regulations.

Improve Troubleshooting – Helps electricians quickly identify and repair faults.

By implementing effective cable marking systems, businesses enhance safety and efficiency.

Choosing the Right Marking System for Your Needs

Selecting the right wire and cable marking solution depends on:

Environmental Conditions – Heat, moisture, and exposure to chemicals affect label durability.

Industry Requirements – Different sectors follow specific wire coding standards.

Cable Type and Size – The diameter and flexibility of the wire impact the labeling method.

At Archford, businesses can find high-quality cable identification tags and labeling solutions to meet industry demands.

Explore the Wire and Cable Marking Guide to learn more about industry-approved marking techniques.

How Archford Provides Quality Cable Marking Solutions

Archford offers a range of industrial wire labeling products designed for:

-

Durability – Resistant to heat, moisture, and wear.

-

Compliance – Meets OSHA cable marking and other safety standards.

-

Efficiency – Simplifies cable identification in complex electrical setups.

By choosing Archford, businesses can enhance electrical cable safety and streamline operations.

The Ultimate Guide to Workplace Safety: Best Practices for Every Industry

|

Safety Guide |

Tips |

|

Implement Sort, Set in Order, Shine, Standardize, and Sustain for workplace efficiency. |

|

|

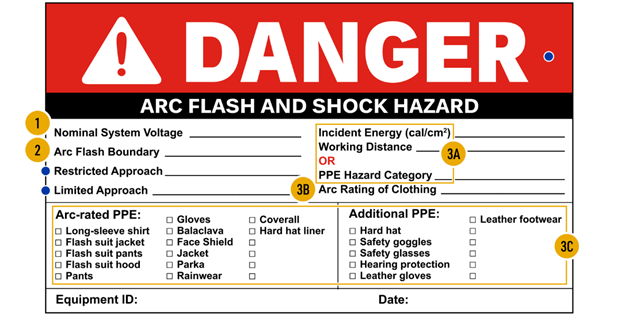

Use proper labels with voltage ratings, approach boundaries, and PPE requirements to ensure electrical safety. |

|

|

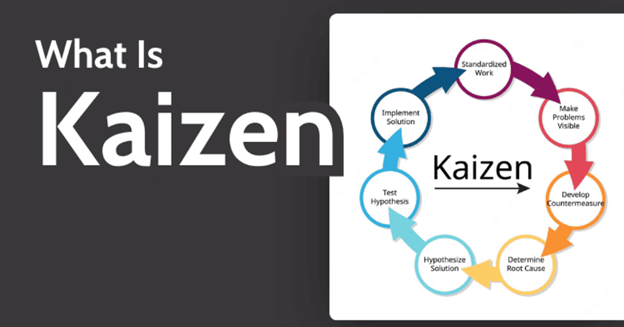

Apply lean methodologies like Kaizen and Six Sigma to enhance operational efficiency. |

|

|

Ensure all hazardous materials are labeled with correct pictograms, signal words, and hazard statements. |

|

|

Use proper lockout devices and tags to prevent accidental energy releases during maintenance. |

|

|

Follow standard color codes and label pipes at regular intervals for easy identification. |

|

|

Place warning signs in high-risk areas to comply with OSHA standards and improve workplace safety. |

|

|

Use AS 1345 standard colors and labels for accurate pipe identification in Australian industries. |

|

|

Add ‘Safety’ to the 5S system to further enhance workplace organization and hazard prevention. |

|

|

Use different colors for specific zones—e.g., red for fire hazards, yellow for caution, and green for safety paths. |

|

|

Encourage small, continuous improvements by involving employees in process optimization. |

|

|

Use visual signals to manage workflow and reduce inefficiencies in production. |

|

|

Implement proper PPE, ventilation, and emergency procedures to ensure worker safety in mining operations. |

|

|

Use durable, heat-resistant labels to prevent misidentification of electrical wiring. |

|

|

Maintain clear aisles, proper signage, and forklift safety measures to reduce accidents. |

|

|

Optimize layout, use barcode scanning, and implement inventory tracking systems for smooth operations. |

|

|

Use consistent signage, color-coded paths, and lighting to improve navigation. |

|

|

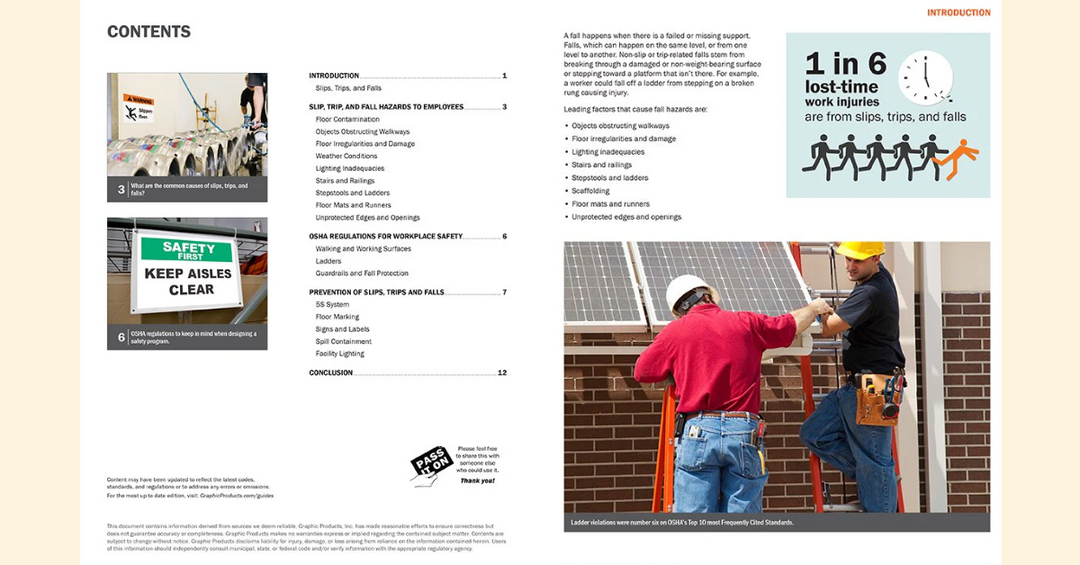

Keep floors dry, use anti-slip mats, and mark hazard areas to prevent workplace injuries. |

|

|

Use labels, floor markings, and visual boards to improve communication and organization. |

|

|

Clearly label valves with durable tags to ensure safe and proper operation. |

Conclusion

Proper wire and cable marking is essential for maintaining safety, compliance, and efficiency in industrial and commercial settings. By using standardized labels, durable materials, and following best practices, businesses can reduce hazards and improve operational workflows.

For reliable wire labeling solutions, check out Archford's Wire and Cable Marking Guide and take a step towards safer and more efficient cable management.

FAQs About Wire and Cable Marking

1. Why is wire and cable marking important?

Proper marking ensures workplace safety, regulatory compliance, and efficient troubleshooting.

2. What are the best cable marking methods?

Popular methods include printed labels, heat shrink tubing, and engraved tags for long-term durability.

3. What industry regulations apply to wire labeling?

Standards such as OSHA cable marking, IEC 60445, and ANSI/TIA-606-C ensure proper identification and safety.

4. How do I choose the right cable marking solution?

Consider environmental conditions, industry regulations, and cable type when selecting a marking system.

5. Where can I find high-quality cable marking products?

Archford offers a variety of industrial wire labeling solutions. Check out their Wire and Cable Marking Guide for more details.