Kanban Guide: Optimize Workflow for Peak Efficiency

Introduction to Kanban

In today’s fast-paced work environment, efficiency and productivity are crucial for success. Businesses across various industries seek streamlined processes to minimize waste, maximize output, and improve collaboration. This is where Kanban comes into play.

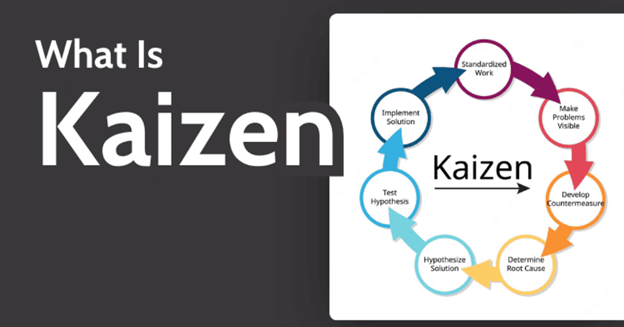

Kanban is a visual workflow management system that enhances productivity by providing real-time insights into work progress. Initially developed in just-in-time manufacturing, Kanban has since been widely adopted across industries, including software development, healthcare, and business operations.

For organizations looking to improve their workflow efficiency, Archford provides resources and tools, including a detailed Kanban Guide to help businesses implement and optimize Kanban effectively.

Core Principles of Kanban

Understanding the fundamental principles of Kanban is essential for successful implementation. These principles guide teams in optimizing workflow, minimizing bottlenecks, and improving overall efficiency.

1. Visualizing Workflow for Better Clarity

Kanban relies on a visual task management system that maps out the workflow stages. By using cards to represent tasks and columns to represent progress stages, teams gain a clear understanding of ongoing work, pending tasks, and completed projects.

2. Limiting Work in Progress (WIP) for Efficiency

Overloading employees with multiple tasks reduces productivity. Kanban limits the number of tasks in progress to maintain focus and efficiency. This helps prevent bottlenecks and ensures smooth task completion.

3. Continuous Flow and Process Improvement

Kanban encourages a steady, uninterrupted workflow. Tasks move seamlessly from one stage to another, reducing downtime and increasing output. The system also promotes continuous improvement, allowing teams to adapt and refine their processes over time.

Kanban Board Setup: How to Get Started

A well-structured Kanban board setup is key to achieving a clean workflow. Setting up an effective Kanban board requires:

Defining Workflow Stages – Establish clear progress stages, such as "To-Do," "In Progress," "Review," and "Done."

Assigning Tasks Clearly – Ensure that team members know their responsibilities.

Limiting Work in Progress (WIP) – Prevent work overload by capping the number of tasks per stage.

Regular Monitoring and Adaptation – Continuously review and improve processes to maintain efficiency.

How Kanban Improves Workflow Efficiency

Kanban is widely recognized for its ability to optimize workflow management and eliminate inefficiencies. Here’s how it transforms business operations:

Reducing Bottlenecks and Delays

One of the biggest advantages of Kanban is its ability to identify bottlenecks early. By monitoring task progress, teams can quickly address obstacles and maintain steady workflow momentum.

Enhancing Team Collaboration and Transparency

Kanban fosters real-time communication and teamwork. Since all team members have access to the Kanban board, everyone stays informed about current workloads, task priorities, and deadlines.

Data-Driven Decision Making

Kanban tools provide valuable performance metrics such as cycle time, lead time, and completed tasks. These insights help businesses make informed decisions to enhance workflow efficiency and optimize resource allocation.

Kanban in Agile Project Management

Kanban plays a vital role in agile project management, offering a flexible approach to task execution. Unlike rigid project management methods, Kanban adapts to real-time changes, allowing teams to prioritize urgent tasks while maintaining overall workflow stability.

By integrating Kanban into agile project management, organizations can:

-

Increase responsiveness to change

-

Improve cross-functional collaboration

-

Enhance task prioritization and tracking

Implementing Kanban in Different Industries

Kanban’s flexibility allows it to be adapted to various industries. Here’s how different sectors use Kanban to streamline operations:

Kanban in Manufacturing

Originally developed by Toyota, Kanban revolutionized just-in-time manufacturing by optimizing inventory management and production efficiency. It helps manufacturers reduce waste, maintain smooth operations, and improve supply chain coordination.

Kanban in Software Development

In the tech industry, Kanban is widely used in Agile development to track software progress. By visualizing coding tasks, bug fixes, and testing phases, software teams ensure faster delivery and high-quality results.

Kanban for Business Operations

From marketing teams tracking campaign progress to customer support teams managing service requests, Kanban helps businesses maintain workflow transparency, task prioritization, and productivity.

Common Challenges and How to Overcome Them

Even though Kanban is a powerful tool, its effectiveness depends on proper implementation. Here are some common challenges and solutions:

Overloading Work in Progress (WIP) – Maintain task limits per team member to prevent work overload.

Lack of Team Alignment – Hold regular meetings to ensure everyone understands the workflow process.

Ignoring Continuous Improvement – Use performance metrics to refine and improve workflows regularly.

Why Kanban is Essential for Modern Workplaces

In today’s fast-moving work environments, Kanban plays a crucial role in enhancing efficiency, reducing waste, and promoting collaboration. It aligns perfectly with lean transformation strategies, making it an essential tool for organizations looking to optimize workflow management.

For a detailed breakdown of Kanban implementation, explore the Kanban Guide by Archford, a trusted resource for workplace efficiency solutions.

The Ultimate Guide to Workplace Safety: Best Practices for Every Industry

|

Safety Guide |

Tips |

|

Implement Sort, Set in Order, Shine, Standardize, and Sustain for workplace efficiency. |

|

|

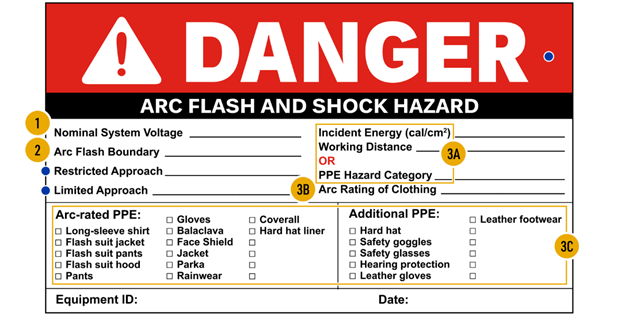

Use proper labels with voltage ratings, approach boundaries, and PPE requirements to ensure electrical safety. |

|

|

Apply lean methodologies like Kaizen and Six Sigma to enhance operational efficiency. |

|

|

Ensure all hazardous materials are labeled with correct pictograms, signal words, and hazard statements. |

|

|

Use proper lockout devices and tags to prevent accidental energy releases during maintenance. |

|

|

Follow standard color codes and label pipes at regular intervals for easy identification. |

|

|

Place warning signs in high-risk areas to comply with OSHA standards and improve workplace safety. |

|

|

Use AS 1345 standard colors and labels for accurate pipe identification in Australian industries. |

|

|

Add ‘Safety’ to the 5S system to further enhance workplace organization and hazard prevention. |

|

|

Use different colors for specific zones—e.g., red for fire hazards, yellow for caution, and green for safety paths. |

|

|

Encourage small, continuous improvements by involving employees in process optimization. |

|

|

Use visual signals to manage workflow and reduce inefficiencies in production. |

|

|

Implement proper PPE, ventilation, and emergency procedures to ensure worker safety in mining operations. |

|

|

Use durable, heat-resistant labels to prevent misidentification of electrical wiring. |

|

|

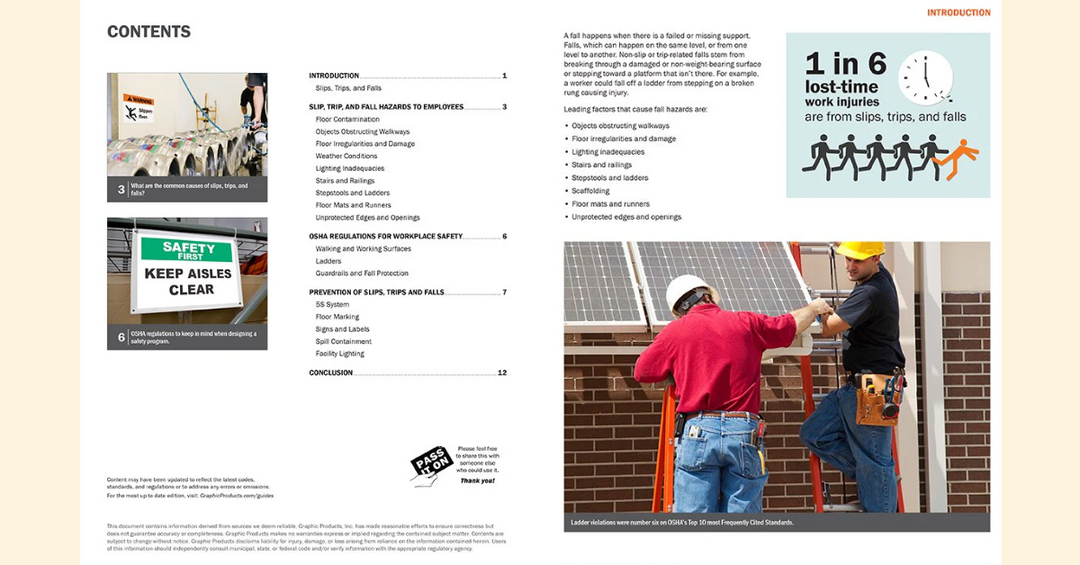

Maintain clear aisles, proper signage, and forklift safety measures to reduce accidents. |

|

|

Optimize layout, use barcode scanning, and implement inventory tracking systems for smooth operations. |

|

|

Use consistent signage, color-coded paths, and lighting to improve navigation. |

|

|

Keep floors dry, use anti-slip mats, and mark hazard areas to prevent workplace injuries. |

|

|

Use labels, floor markings, and visual boards to improve communication and organization. |

|

|

Clearly label valves with durable tags to ensure safe and proper operation. |

Conclusion

Kanban is a powerful tool that helps businesses visualize tasks, improve efficiency, and promote continuous improvement. Whether in manufacturing, software development, or business operations, Kanban enables organizations to optimize workflows and enhance team productivity.

For expert guidance and industry-leading resources, check out Archford’s Kanban Guide and start transforming your workflow today!

FAQs About Kanban

1. What is the main purpose of Kanban?

Kanban is a workflow management system that improves efficiency by visualizing tasks, limiting work in progress, and promoting continuous improvement.

2. How does Kanban differ from Scrum?

Unlike Scrum, which follows a structured sprint-based approach, Kanban focuses on continuous workflow without fixed time constraints.

3. Can Kanban be used outside of manufacturing and software development?

Yes! Kanban is widely used in business operations, marketing, HR, healthcare, and customer service to enhance efficiency.

4. What are the key benefits of implementing Kanban?

Kanban helps businesses reduce bottlenecks, improve collaboration, track performance, and optimize resource allocation.

5. How do I get started with Kanban?

Begin with a simple Kanban board, define work stages, set task limits, and gradually refine your process for better efficiency. You can explore Archford’s detailed Kanban Guide for in-depth guidance.