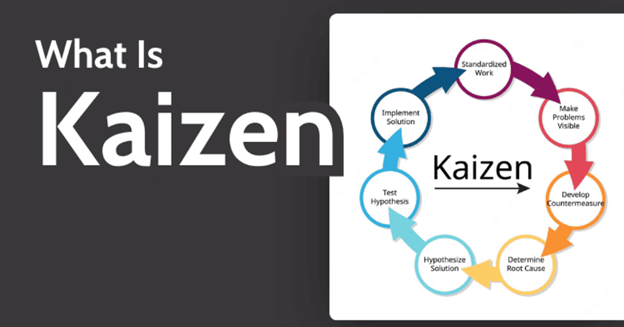

Kaizen Guide: Best Practices for Sustainable Growth

Introduction to Kaizen

In today’s fast-paced business environment, organizations must continuously evolve to stay competitive. One of the most effective ways to drive long-term success is by implementing Kaizen, a Japanese methodology focused on continuous improvement. By making small incremental changes over time, businesses can achieve significant improvements in productivity, efficiency, and workplace culture.

At Archford, we understand the power of Kaizen and how it can transform businesses across industries. Whether you're looking to enhance operational efficiency or create a culture of innovation, this guide will help you understand the core principles and best practices for effective Kaizen implementation.

The Core Principles of Kaizen

Kaizen is built on several fundamental principles that guide businesses toward sustainable growth:

-

Continuous Improvement Process – The belief that every process can be improved, no matter how efficient it already seems.

-

Eliminating Waste – Reducing inefficiencies, such as excessive inventory, unnecessary movement, and production defects.

-

Standardization – Establishing best practices that ensure consistency in workflows.

-

Employee Involvement – Encouraging employees at all levels to contribute ideas for improvement.

-

Data-Driven Decision Making – Using performance metrics and analytics to identify areas that need enhancement.

By adhering to these principles, companies can foster a culture of efficiency and long-term success.

How Kaizen Drives Sustainable Growth

Sustainable growth is not about short-term success but long-term progress. Kaizen helps businesses achieve this by:

-

Improving process efficiency, reducing waste, and optimizing resource utilization.

-

Encouraging employee engagement, making workers feel valued and motivated.

-

Creating a culture of accountability, where teams take ownership of improvements.

-

Enhancing customer satisfaction by consistently delivering high-quality products and services.

Companies that embrace Kaizen find themselves more adaptable to changing market conditions, giving them a competitive advantage.

Kaizen in Manufacturing: A Game Changer

One of the most well-known applications of Kaizen is in the manufacturing industry. Kaizen in manufacturing has revolutionized production processes by:

-

Reducing defects through better quality control and standardization.

-

Enhancing workflow efficiency by minimizing delays and unnecessary steps.

-

Lowering costs by eliminating waste and optimizing material use.

-

Improving worker safety by promoting a well-organized and hazard-free environment.

Global giants like Toyota have successfully applied Kaizen in manufacturing, setting industry benchmarks for efficiency and productivity.

Steps for Effective Kaizen Implementation

To successfully integrate Kaizen, follow these key steps:

1. Identify Areas for Improvement

Analyze current workflows and look for bottlenecks, inefficiencies, or quality issues.

2. Involve Employees

Encourage employees to share ideas and suggestions for process improvements.

3. Implement Small Incremental Changes

Instead of making drastic overhauls, start with small incremental changes that improve workflows gradually.

4. Monitor and Measure Progress

Track the impact of changes using performance metrics and adjust strategies as needed.

5. Standardize Best Practices

Once a successful improvement is made, document it and integrate it into standard workflows.

By following these steps, organizations can create a Kaizen-driven environment that fosters ongoing development.

Key Benefits of the Kaizen Approach

The Kaizen methodology offers several advantages, including:

-

Enhanced efficiency – Streamlining processes to reduce waste.

-

Higher quality output – Continuous refinements lead to better products and services.

-

Cost savings – Reducing waste and inefficiencies translates to lower operational costs.

-

Greater employee satisfaction – Workers feel empowered when they contribute to company improvements.

-

Stronger company culture – A workplace focused on continuous improvement fosters innovation and teamwork.

These benefits make Kaizen a valuable strategy for businesses of all sizes.

Kaizen vs. Lean Transformation

Many companies wonder whether they should pursue Kaizen or a full lean transformation. While both methodologies aim to improve efficiency, they have key differences:

|

Feature |

Kaizen |

Lean Transformation |

|

Approach |

Gradual, ongoing improvements |

Large-scale organizational change |

|

Cost |

Low-cost, continuous |

Higher initial investment |

|

Employee Involvement |

Encourages all employees |

Requires strong leadership direction |

|

Risk Level |

Low risk |

Can be high risk if not implemented properly |

|

Flexibility |

Highly adaptable |

Requires structured execution |

For businesses seeking sustainable growth, integrating Kaizen into a lean transformation strategy can offer long-term success with minimal disruption.

The Role of Leadership in Kaizen

Leadership plays a crucial role in Kaizen’s success. Managers and executives must:

-

Encourage innovation – Support employees in proposing and testing new ideas.

-

Provide resources – Allocate necessary tools and training for continuous improvement.

-

Lead by example – Show commitment to Kaizen by actively participating in improvement efforts.

-

Recognize contributions – Reward employees who contribute to process enhancements.

By fostering a Kaizen-friendly environment, leaders ensure long-term business success.

Challenges and Solutions in Kaizen Implementation

While Kaizen is highly effective, businesses may face obstacles, such as:

1. Resistance to Change

Employees may hesitate to adopt new practices. Solution: Provide training and highlight benefits.

2. Lack of Immediate Results

Kaizen takes time to show impact. Solution: Focus on small incremental changes with measurable outcomes.

3. Inconsistent Adoption

Some departments may embrace Kaizen more than others. Solution: Standardize best practices across the company.

Overcoming these challenges ensures Kaizen becomes an integral part of your business strategy.

How Archford Supports Kaizen Implementation

At Archford, we provide businesses with the tools and resources needed to implement and sustain Kaizen. Our comprehensive Kaizen Guide offers valuable insights into best practices, strategies, and real-world applications to help companies maximize efficiency and growth.

Whether you’re just starting with Kaizen or looking to refine your current approach, Archford is here to support your journey toward continuous improvement.

The Ultimate Guide to Workplace Safety: Best Practices for Every Industry

|

Safety Guide |

Tips |

|

Implement Sort, Set in Order, Shine, Standardize, and Sustain for workplace efficiency. |

|

|

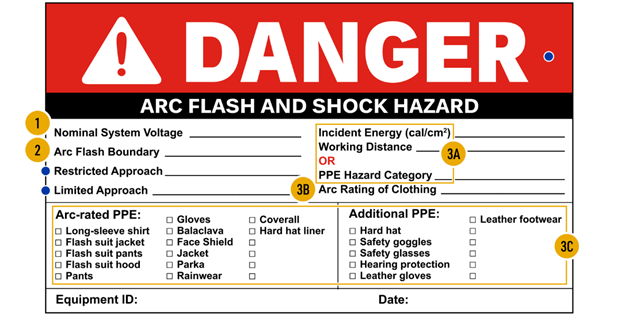

Use proper labels with voltage ratings, approach boundaries, and PPE requirements to ensure electrical safety. |

|

|

Apply lean methodologies like Kaizen and Six Sigma to enhance operational efficiency. |

|

|

Ensure all hazardous materials are labeled with correct pictograms, signal words, and hazard statements. |

|

|

Use proper lockout devices and tags to prevent accidental energy releases during maintenance. |

|

|

Follow standard color codes and label pipes at regular intervals for easy identification. |

|

|

Place warning signs in high-risk areas to comply with OSHA standards and improve workplace safety. |

|

|

Use AS 1345 standard colors and labels for accurate pipe identification in Australian industries. |

|

|

Add ‘Safety’ to the 5S system to further enhance workplace organization and hazard prevention. |

|

|

Use different colors for specific zones—e.g., red for fire hazards, yellow for caution, and green for safety paths. |

|

|

Encourage small, continuous improvements by involving employees in process optimization. |

|

|

Use visual signals to manage workflow and reduce inefficiencies in production. |

|

|

Implement proper PPE, ventilation, and emergency procedures to ensure worker safety in mining operations. |

|

|

Use durable, heat-resistant labels to prevent misidentification of electrical wiring. |

|

|

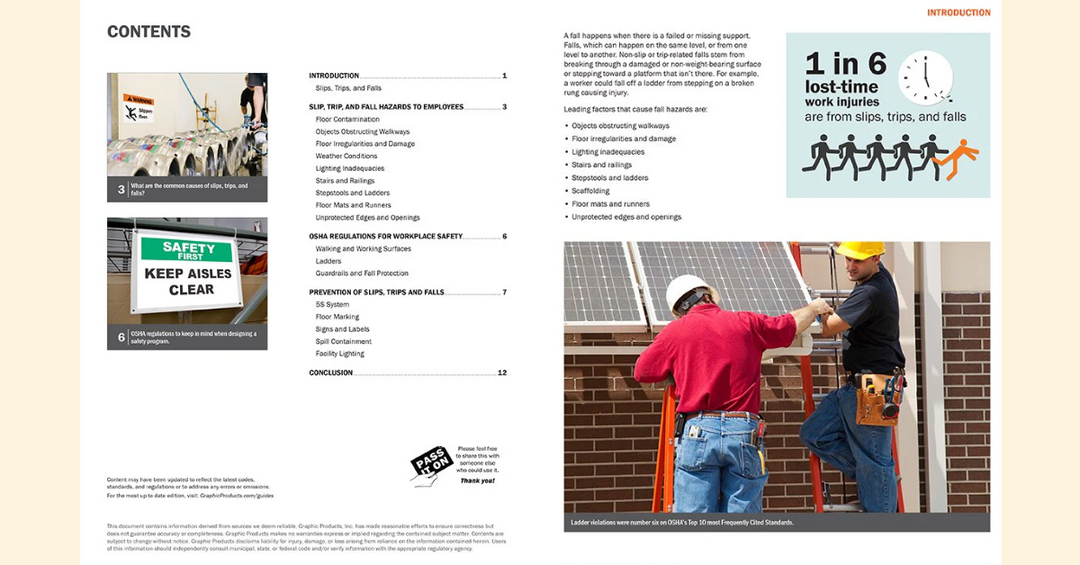

Maintain clear aisles, proper signage, and forklift safety measures to reduce accidents. |

|

|

Optimize layout, use barcode scanning, and implement inventory tracking systems for smooth operations. |

|

|

Use consistent signage, color-coded paths, and lighting to improve navigation. |

|

|

Keep floors dry, use anti-slip mats, and mark hazard areas to prevent workplace injuries. |

|

|

Use labels, floor markings, and visual boards to improve communication and organization. |

|

|

Clearly label valves with durable tags to ensure safe and proper operation. |

Conclusion

The Kaizen methodology is a proven approach to achieving sustainable business growth through continuous improvement. By implementing Kaizen principles, companies can enhance efficiency, reduce waste, and create a culture of innovation.

For expert guidance and resources on Kaizen, visit Archford and explore our Kaizen Guide to take your business to the next level.

Frequently Asked Questions (FAQs)

1. What is the main goal of Kaizen?

The primary goal of Kaizen is to drive continuous improvement through small, incremental changes that enhance efficiency and quality.

2. How does Kaizen differ from Six Sigma?

While Kaizen focuses on continuous small improvements, Six Sigma emphasizes data-driven problem-solving to eliminate defects.

3. Can Kaizen be applied in non-manufacturing industries?

Yes, Kaizen is used in healthcare, retail, logistics, and many other industries to improve processes and customer satisfaction.

4. How long does it take to see results from Kaizen?

Kaizen delivers gradual improvements, with visible changes often occurring within weeks to months.

5. How can businesses encourage employees to adopt Kaizen?

Providing training, incentives, and leadership support can help employees embrace Kaizen principles.