Innovative Warehouse Safety Ideas to Reduce Risks

Introduction:The Importance of Warehouse Safety

Warehouse safety is a top priority for businesses that operate in high-traffic storage environments. With employees, machinery, and inventory constantly in motion, the risk of accidents is always present. Falls, forklift incidents, and improper handling of goods can lead to serious injuries or fatalities.

Implementing effective safety strategies ensures that warehouses remain safe, efficient, and compliant with industry regulations. A proactive approach to workplace hazards helps reduce accidents, lower costs, and improve overall productivity.

Identifying and Addressing Common Warehouse Risks

Warehouses present a variety of risks that must be identified and mitigated:

Slips, Trips, and Falls: Uneven floors, cluttered aisles, and liquid spills increase accident risks.

Heavy Equipment Accidents: Poor forklift safety measures can lead to collisions and worker injuries.

Hazardous Material Handling: Chemicals and flammable substances require proper storage and labeling.

Falling Inventory: Inadequate shelving and improper stacking contribute to dangerous conditions.

Addressing these risks through clear safety protocols and regular inspections can significantly improve warehouse security.

Implementing an Effective Warehouse Safety Plan

A well-structured safety plan reduces the likelihood of accidents and ensures smooth operations. Steps include:

Regular Safety Audits: Conducting routine inspections helps identify potential risks.

Employee Training: Workers must be trained on handling materials, emergency responses, and safety protocols.

Clear Safety Policies: Establishing guidelines for operating machinery and handling inventory minimizes risks.

A culture of safety begins with proper training and strict adherence to safety policies.

Smart Warehouse Layout and Organization

Proper warehouse organization plays a key role in storage safety and accident prevention. Best practices include:

Designated Walkways: Marking separate zones for pedestrians and vehicles prevents collisions.

Safe Stacking of Inventory: Shelving should be sturdy and loads evenly distributed to prevent collapses.

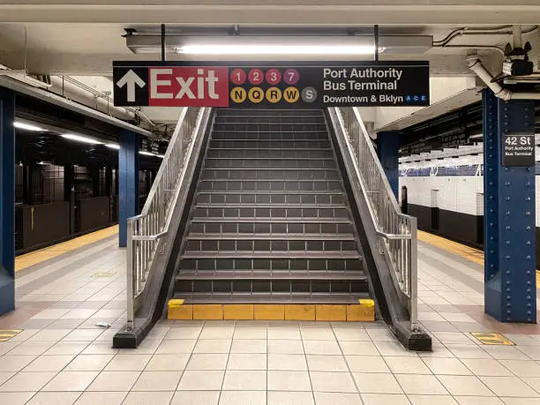

Emergency Exit Accessibility: Keeping pathways clear ensures quick and safe evacuations.

A well-planned layout not only enhances efficiency but also minimizes risks for workers and equipment operators.

The Role of Safety Tags and Signage in Warehouses

Safety signage and tags are essential for ensuring a safe warehouse environment. Their benefits include:

Clear Hazard Identification: Marking danger zones reduces accidents.

Color-Coded Labels: Helps employees quickly recognize restricted areas, emergency exits, and safety equipment locations.

Routine Signage Updates: Replacing worn-out tags ensures up-to-date safety communication.

By using clear signage, businesses enhance workplace awareness and improve compliance with safety regulations.

Cutting-edge technology for Warehouse Safety

Advancements in technology are making warehouses safer and more efficient. Modern solutions include:

Automated Monitoring Systems: Cameras and AI-powered sensors detect unsafe behaviors in real time.

Wearable Safety Gear: Smart helmets and vests provide alerts for hazardous conditions.

Environmental Sensors: Monitors detect gas leaks, temperature changes, and fire risks.

By integrating these technologies, businesses can significantly reduce the occurrence of accidents.

Warehouse Floor Marking Strategies

How to improve warehouse safety? One of the simplest and most effective methods is through floor marking. The benefits include:

Guided Traffic Flow: Clearly defined paths for workers and vehicles reduce confusion.

Defined Safety Areas: Warehouse safety zones help keep hazardous areas separate from working spaces.

Color-Coded Systems: Using color coding for different sections improves workplace organization.

Well-planned warehouse marking improves both safety and efficiency in daily operations.

Best Practices for Material Handling Safety

Proper handling of materials prevents damage and injuries. The best warehouse safety practices include:

Correct Lifting Techniques: Employees should be trained on proper lifting methods to avoid injuries.

Forklift Operation Guidelines: Strict forklift safety rules prevent crashes and equipment damage.

Securing Loads: Proper stacking and restraint methods keep inventory stable and secure.

Encouraging workers to follow these guidelines significantly reduces workplace injuries and property damage.

Fire and Emergency Preparedness in Warehouses

Fire safety is a critical aspect of warehouse management. Essential steps include:

Installing Fire Suppression Systems: Sprinklers and alarms help prevent major fire incidents.

Evacuation Planning: Employees should be familiar with escape routes and assembly points.

Safe Chemical Storage: Hazardous substances must be stored in fire-resistant containers.

Regular emergency drills ensure workers are prepared for any unexpected situations.

Warehouse Safety Compliance and Regulations

Warehouses must comply with industry safety regulations to avoid legal issues. Important aspects include:

Adhering to OSHA Standards: Following workplace safety laws reduces liability.

Routine Equipment Inspections: Regular maintenance checks prevent equipment malfunctions.

Encouraging Employee Participation: Workers should report hazards and contribute to safety improvements.

Ensuring compliance with regulations fosters a safe working environment for all employees.

Top Safety Tag Ideas to Improve Workplace Safety

|

Safety Tags |

Short Description |

|

Explore creative safety tag ideas that can help improve safety communication and compliance in the workplace. |

|

|

Learn effective floor marking ideas to organize workspaces, improve traffic flow, and enhance safety in various environments. |

|

|

Discover warehouse safety ideas that help reduce risks, improve operations, and create a safer working environment. |

|

|

Check out innovative workplace safety tag ideas designed to improve hazard communication and reduce workplace injuries. |

|

|

A comprehensive guide to safety signage ideas that enhance visibility, promote safety awareness, and meet regulatory standards. |

|

|

Get ideas for industrial labeling that ensures proper hazard identification, equipment safety, and regulatory compliance. |

|

|

Explore the best safety tag ideas specifically designed for factories to improve safety measures and operational efficiency. |

Conclusion

By implementing these warehouse safety strategies, businesses can reduce risks, protect employees, and improve efficiency. A well-organized warehouse with clear safety protocols, modern technology, and a strong focus on employee well-being creates a secure work environment.

Taking proactive steps today will lead to a safer, more productive warehouse in the future.

For more safety solutions and compliance tools, visit the Archford Safety Tags page.

By following these strategies, businesses can ensure a safer and more efficient warehouse environment.

FAQs

1. What are the biggest hazards in warehouses?

Common workplace hazards include falls, forklift accidents, fire risks, and improper handling of hazardous materials.

2. How can storage safety be improved in warehouses?

Storage safety can be enhanced by using sturdy shelving, stacking inventory properly, and keeping aisles clear.

3. Why is forklift safety important?

Forklift safety is crucial because improper operation can lead to serious injuries, equipment damage, and workplace accidents.

4. What is the best way to improve warehouse safety?

How to improve warehouse safety? Regular safety audits, employee training, proper signage, and adopting modern safety technology are key.

5. What are the best warehouse safety practices?

The best warehouse safety practices include risk assessments, designated pedestrian zones, strict equipment guidelines, and emergency preparedness plans.