Mastering Lean Management: 6S System Guide

In today’s fast-paced work environment, efficiency, organization, and safety are critical to success. The 6S System is a structured methodology designed to optimize workplaces, reduce waste, and improve productivity. It builds upon the 5S System by adding a crucial element—safety—making it a valuable tool for industries focused on lean manufacturing.

This guide explores the 6S System, its benefits, implementation steps, and how businesses can integrate it for long-term success.

Introduction to the 6S System

The 6S System is a workplace organization method derived from lean manufacturing principles. It focuses on sorting, organizing, cleaning, standardizing, sustaining, and ensuring safety. By following these six principles, companies create structured work environments that enhance workplace efficiency and minimize hazards.

Many organizations worldwide implement 6S to maintain continuous improvement and safety in lean manufacturing, particularly in industries such as manufacturing, construction, healthcare, and warehousing.

The Evolution from 5S to 6S

Originally, 5S was a Japanese methodology focusing on five core principles:

-

Sort (Seiri) – Removing unnecessary items.

-

Set in Order (Seiton) – Organizing work areas efficiently.

-

Shine (Seiso) – Keeping spaces clean and free of hazards.

-

Standardize (Seiketsu) – Establishing clear procedures.

-

Sustain (Shitsuke) – Maintaining discipline for long-term success.

While 5S improved organization and efficiency, it lacked a critical component: safety. That’s where 6S comes in, incorporating safety as the sixth pillar, ensuring that work environments prioritize employee well-being alongside productivity.

Understanding the Six Pillars of 6S

1. Sort (Seiri)

Eliminate unnecessary tools, materials, or equipment to reduce clutter and enhance efficiency.

2. Set in Order (Seiton)

Organize tools and materials in logical, easy-to-access locations to save time and improve workflow.

3. Shine (Seiso)

Regular cleaning routines prevent hazards, ensuring a safer and more efficient workspace.

4. Standardize (Seiketsu)

Develop consistent processes for cleaning, organizing, and maintaining order. This step ensures that best practices become habits.

5. Sustain (Shitsuke)

Encourage long-term adherence to the 6S lean principles through training, audits, and employee engagement.

6. Safety (The Sixth "S")

A safe workspace is a productive workspace. 6S emphasizes hazard prevention, emergency preparedness, and ensuring all safety measures are in place.

Key Benefits of Implementing 6S

-

Increased Productivity: Reduced waste and clutter improve efficiency.

-

Improved Safety: Fewer hazards lead to fewer workplace injuries.

-

Better Employee Morale: A structured and safe environment boosts employee satisfaction.

-

Enhanced Quality Control: A cleaner, more organized space results in fewer errors and defects.

-

Regulatory Compliance: Many industries require safety and organizational standards that 6S helps maintain.

6S vs. 5S: Key Differences

A common question in lean management is how 6S vs. 5S compares. While both methods improve workplace organization and efficiency, 6S explicitly integrates safety, making it more suitable for hazardous work environments.

Industries dealing with heavy machinery, chemicals, or high-risk tasks benefit significantly from 6S due to its focus on minimizing safety risks.

How the 6S System Enhances Lean Management

Lean management is about reducing waste and maximizing value. 6S complements lean strategies by creating a structured, hazard-free environment that allows businesses to operate smoothly and efficiently.

By eliminating unnecessary steps, organizing workstations, and ensuring safety compliance, businesses can significantly cut down on wasted time and materials while fostering a culture of continuous improvement.

Steps to Successfully Implement the 6S System

-

Assess the Current Workplace: Identify clutter, inefficiencies, and potential safety hazards.

-

Educate Employees: Train teams on 6S principles and the benefits of implementation.

-

Organize and Label Work Areas: Implement visual management tools like labels, floor markings, and signs.

-

Create a Cleaning and Maintenance Plan: Assign cleaning responsibilities to ensure ongoing workplace organization.

-

Standardize Best Practices: Develop written guidelines and checklists for employees to follow.

-

Monitor and Improve: Conduct regular audits and encourage employee feedback to refine the process continually.

The Role of archford in 6S Implementation

archford provides high-quality safety and organizational solutions to help businesses effectively implement 6S. From visual management tools to customized workplace safety solutions, .archford ensures businesses comply with industry best practices.

For expert resources on implementing the 6S Safety Guide, visit archford.

Best Practices for Long-Term 6S Success

-

Engage Employees: Encourage active participation in 6S initiatives.

-

Use Visual Aids: Floor markings, signs, and labels reinforce organization.

-

Schedule Regular Audits: Ensure adherence to 6S standards through consistent monitoring.

-

Recognize and Reward Compliance: Acknowledge teams that maintain 6S principles effectively.

The Ultimate Guide to Workplace Safety: Best Practices for Every Industry

|

Safety Guide |

Tips |

|

Implement Sort, Set in Order, Shine, Standardize, and Sustain for workplace efficiency. |

|

|

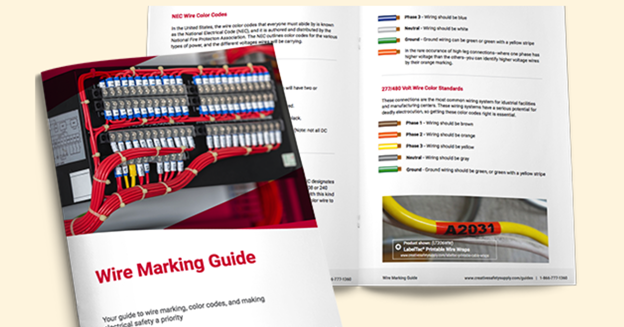

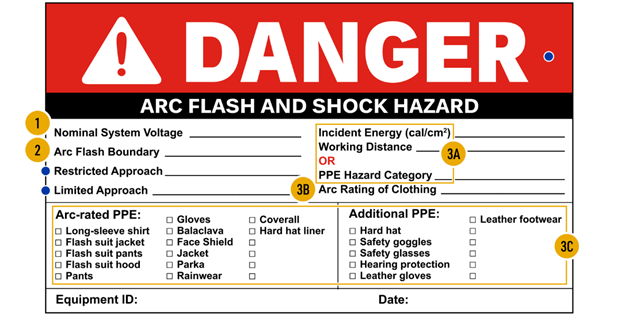

Use proper labels with voltage ratings, approach boundaries, and PPE requirements to ensure electrical safety. |

|

|

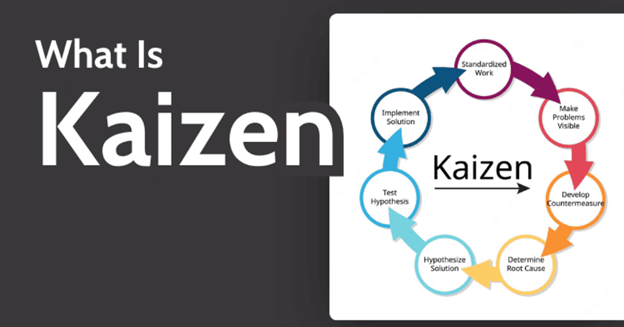

Apply lean methodologies like Kaizen and Six Sigma to enhance operational efficiency. |

|

|

Ensure all hazardous materials are labeled with correct pictograms, signal words, and hazard statements. |

|

|

Use proper lockout devices and tags to prevent accidental energy releases during maintenance. |

|

|

Follow standard color codes and label pipes at regular intervals for easy identification. |

|

|

Place warning signs in high-risk areas to comply with OSHA standards and improve workplace safety. |

|

|

Use AS 1345 standard colors and labels for accurate pipe identification in Australian industries. |

|

|

Add ‘Safety’ to the 5S system to further enhance workplace organization and hazard prevention. |

|

|

Use different colors for specific zones—e.g., red for fire hazards, yellow for caution, and green for safety paths. |

|

|

Encourage small, continuous improvements by involving employees in process optimization. |

|

|

Use visual signals to manage workflow and reduce inefficiencies in production. |

|

|

Implement proper PPE, ventilation, and emergency procedures to ensure worker safety in mining operations. |

|

|

Use durable, heat-resistant labels to prevent misidentification of electrical wiring. |

|

|

Maintain clear aisles, proper signage, and forklift safety measures to reduce accidents. |

|

|

Optimize layout, use barcode scanning, and implement inventory tracking systems for smooth operations. |

|

|

Use consistent signage, color-coded paths, and lighting to improve navigation. |

|

|

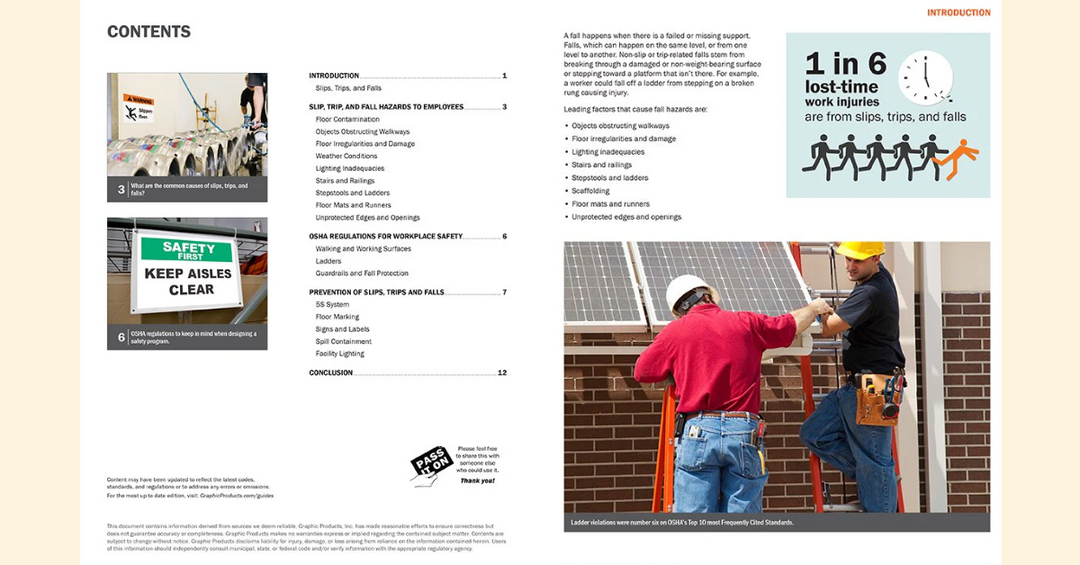

Keep floors dry, use anti-slip mats, and mark hazard areas to prevent workplace injuries. |

|

|

Use labels, floor markings, and visual boards to improve communication and organization. |

|

|

Clearly label valves with durable tags to ensure safe and proper operation. |

Conclusion

The 6S System enhances workplace efficiency, safety, and organization through structured lean principles. By integrating safety into 5S, it ensures a cleaner, more productive, and hazard-free environment. To implement 6S effectively, explore archford’s for expert solutions.

FAQs

1. What is the difference between 5S and 6S?

The 5S System focuses on organization and efficiency, while 6S adds safety as a crucial component, ensuring a hazard-free work environment.

2. Why is the 6S System important in the workplace?

It improves workplace efficiency, safety, and productivity, helping businesses reduce waste and prevent workplace hazards.

3. How does 6S relate to lean management?

The 6S System supports lean principles by eliminating inefficiencies and ensuring a well-structured work environment.

4. Can the 6S System be applied outside of manufacturing?

Yes! Healthcare, warehousing, retail, and construction all benefit from 6S implementation.

5. How can businesses maintain 6S standards over time?

Regular audits, employee training, and management support ensure long-term adherence to 6S principles.