GHS Labeling Guide: How to Ensure Workplace Safety

Introduction to GHS Labeling

Hazardous chemicals are widely used across industries, making chemical safety labeling essential for ensuring a safe work environment. The Globally Harmonized System (GHS) of Classification and Labeling of Chemicals provides a standardized approach to hazard communication, ensuring that employees understand the risks associated with various substances.

By following GHS compliance guidelines, businesses can reduce risks, improve workplace safety, and meet legal requirements. Companies looking for safety labeling solutions can rely on .Archford for high-quality labels, compliance resources, and expert guidance.

Why GHS Labeling Matters in Workplace Safety

Effective hazard communication standard practices help businesses maintain a safe and compliant workplace. Proper labeling ensures:

Accident Prevention: Employees can quickly identify chemical hazards and take necessary precautions.

Regulatory Compliance: Organizations comply with OSHA hazard labels requirements and international regulations.

Environmental Protection: Reduces the risk of chemical spills and contamination.

Emergency Preparedness: Quick hazard identification allows for swift emergency response.

By implementing GHS-compliant labeling, companies can enhance workplace chemical management and minimize safety risks.

Key Components of a GHS Label

Each GHS label consists of essential elements that communicate vital safety information.

1. Hazard Pictograms

These symbols, enclosed in red diamonds, visually represent different hazards, including:

-

Flame: Flammable substances

-

Skull and Crossbones: Toxic chemicals

-

Corrosion: Skin irritation and corrosive materials

.

2. Hazard and Precautionary Statements

- Hazard Statements: Explain potential dangers (e.g., "Causes serious eye damage").

-

Precautionary Statements: Provide safety instructions (e.g., "Wear protective gloves").

3. Signal Words

- Danger: Used for severe hazards.

- Warning: Used for less severe hazards

Understanding these GHS labeling components ensures effective hazard communication in the workplace.

Meeting GHS Compliance and OSHA Standards

To ensure GHS compliance, businesses must:

Classify Chemicals Correctly: Identify hazardous properties of substances.

Use Proper Label Formats: Follow OSHA hazard labels requirements.

Maintain Safety Data Sheets (SDS): Keep updated records for each chemical.

Train Employees: Workers must understand how to read chemical safety labeling.

Companies failing to comply with hazard communication standards may face legal penalties and increased workplace hazards. To ensure compliance, businesses can turn to .Archford for high-quality GHS labeling solutions.

Common Challenges in GHS Labeling and How to Overcome Them

Challenge: Difficulty in classifying chemicals correctly.

Solution: Use regulatory guidelines and GHS labeling software.

Challenge: Labels fading due to harsh conditions.

Solution: Use durable safety labels from .Archford, designed for industrial environments.

Challenge: Keeping up with changing regulations.

Solution: Regularly update workplace chemical management policies and labels.

By addressing these challenges, businesses can improve hazard communication and maintain a safe working environment.

Best Practices for Implementing GHS Labeling

Standardize Labeling Procedures: Ensure uniformity across all chemical containers.

Regularly Inspect Labels: Replace any faded or missing labels.

Provide Employee Training: Educate workers on GHS compliance and safe handling.

Use High-Quality Labels: Invest in long-lasting, OSHA-compliant labels from .Archford.

By following these best practices, businesses can enhance workplace safety and regulatory compliance.

How .Archford Supports GHS Labeling Compliance

For businesses seeking GHS labeling solutions, .Archford offers:

GHS-Compliant Safety Labels – Durable, high-quality labeling for industrial use.

Regulatory Compliance Support – Expert guidance on chemical safety labeling.

Custom Label Printing Guides – Resources for creating accurate and compliant labels.

Explore the GHS Labeling Guide to simplify workplace chemical management.

The Ultimate Guide to Workplace Safety: Best Practices for Every Industry

|

Safety Guide |

Tips |

|

Implement Sort, Set in Order, Shine, Standardize, and Sustain for workplace efficiency. |

|

|

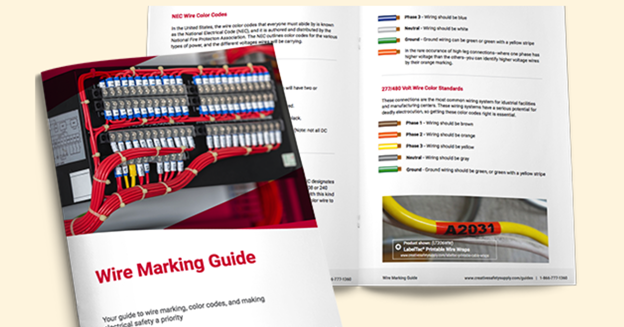

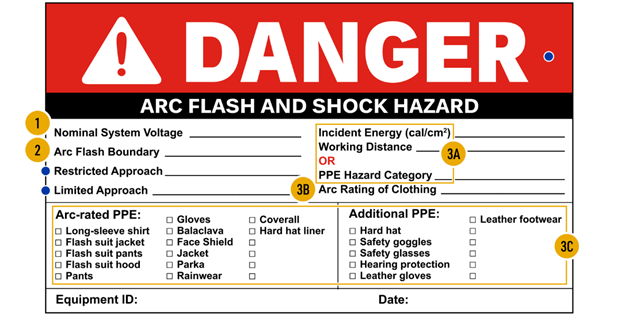

Use proper labels with voltage ratings, approach boundaries, and PPE requirements to ensure electrical safety. |

|

|

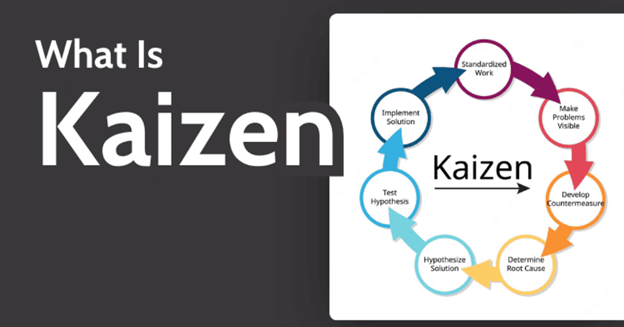

Apply lean methodologies like Kaizen and Six Sigma to enhance operational efficiency. |

|

|

Ensure all hazardous materials are labeled with correct pictograms, signal words, and hazard statements. |

|

|

Use proper lockout devices and tags to prevent accidental energy releases during maintenance. |

|

|

Follow standard color codes and label pipes at regular intervals for easy identification. |

|

|

Place warning signs in high-risk areas to comply with OSHA standards and improve workplace safety. |

|

|

Use AS 1345 standard colors and labels for accurate pipe identification in Australian industries. |

|

|

Add ‘Safety’ to the 5S system to further enhance workplace organization and hazard prevention. |

|

|

Use different colors for specific zones—e.g., red for fire hazards, yellow for caution, and green for safety paths. |

|

|

Encourage small, continuous improvements by involving employees in process optimization. |

|

|

Use visual signals to manage workflow and reduce inefficiencies in production. |

|

|

Implement proper PPE, ventilation, and emergency procedures to ensure worker safety in mining operations. |

|

|

Use durable, heat-resistant labels to prevent misidentification of electrical wiring. |

|

|

Maintain clear aisles, proper signage, and forklift safety measures to reduce accidents. |

|

|

Optimize layout, use barcode scanning, and implement inventory tracking systems for smooth operations. |

|

|

Use consistent signage, color-coded paths, and lighting to improve navigation. |

|

|

Keep floors dry, use anti-slip mats, and mark hazard areas to prevent workplace injuries. |

|

|

Use labels, floor markings, and visual boards to improve communication and organization. |

|

|

Clearly label valves with durable tags to ensure safe and proper operation. |

Conclusion

Proper GHS labeling plays a crucial role in workplace chemical management and hazard communication. By following GHS compliance guidelines and using high-quality chemical safety labeling, businesses can protect employees and the environment.

For GHS labeling solutions and expert support, visit .Archford and download the GHS Labeling Guide today!

FAQs About GHS Labeling

1. Why is GHS labeling important?

It ensures workplace safety, legal compliance, and effective hazard communication.

2. Do all chemicals require GHS labels?

Yes, any hazardous substance must have a GHS-compliant label.

3. How often should GHS labels be reviewed?

Labels should be updated when:

-

Chemical properties change.

-

New safety regulations are introduced.

4. What happens if a business does not comply with GHS regulations?

Non-compliance can result in fines, legal actions, and increased workplace hazards.

5. Where can I get high-quality GHS labels?

.Archford provides durable, OSHA-compliant GHS labels. Visit GHS Labeling Guide for details.