OSHA Safety Signs Guide: How to Prevent Workplace Hazards

Introduction to OSHA Safety Signs

Workplace safety is a top priority for any organization, and one of the most effective ways to ensure a safe environment is by using OSHA safety signs. These signs play a crucial role in alerting workers, visitors, and contractors to potential hazards, safety protocols, and emergency exits.

Following proper safety sign regulations helps businesses comply with OSHA (Occupational Safety and Health Administration) standards, reducing the risk of accidents and injuries. In this guide, we’ll explore the importance of safety signs, the different types required for workplace compliance, and best practices for using them effectively.

At .Archford, we provide high-quality safety signs that meet OSHA standards, ensuring that your workplace remains safe and compliant. Learn more about workplace safety solutions at .Archford.

Why Workplace Safety Signs Are Essential

Safety signs are more than just labels on walls—they are life-saving tools that prevent injuries and ensure smooth operations. Proper signage:

-

Warns employees about potential hazards

-

Provides clear instructions for safe operations

-

Helps organizations meet regulatory requirements

-

Improves workplace safety culture

By implementing OSHA safety signs, businesses can create a safer work environment while avoiding fines and legal issues related to non-compliance.

Understanding OSHA Safety Sign Categories

1. Warning Signs

These signs indicate a potential hazard that could result in serious injury. They are typically orange with black text and symbols. Example: “High Voltage – Keep Out.”

2. Danger Signs

Danger signs represent immediate hazards that could cause death or severe injury. They use red, black, and white colors for visibility. Example: “Confined Space – Do Not Enter.”

3. Caution Signs

These signs warn of minor hazards that require precaution. They are yellow with black text. Example: “Wet Floor – Slippery Surface.”

4. Emergency Signs

These provide directions to emergency exits, first aid stations, or safety equipment. They are green with white text. Example: “First Aid Kit Inside.”

Each category serves a unique purpose, ensuring workplaces can handle potential hazards effectively.

OSHA Compliance and Safety Sign Regulations

OSHA has strict regulations regarding workplace safety signs. To ensure compliance, businesses must:

-

Use standardized colors and symbols

-

Place signs where hazards are present

-

Ensure signs are visible and easy to read

-

Regularly inspect and maintain safety signs

Failure to comply with OSHA safety sign guidelines can lead to penalties and legal consequences. Keeping up with the latest regulations is essential for businesses.

Proper Placement of Safety Signs in the Workplace

Strategic placement of safety signs is crucial for maximum effectiveness. Here are key locations where OSHA signs should be displayed:

-

Entry Points: To warn employees and visitors about potential hazards

-

Work Areas: Near machinery, hazardous chemicals, or confined spaces

-

Exits and Stairwells: To indicate emergency exit signage for quick evacuations

-

Storage Areas: For flammable materials, electrical equipment, or hazardous substances

Regular audits help businesses identify missing or outdated safety signs that need replacement.

The Role of ANSI Safety Signs in Workplace Compliance

In addition to OSHA regulations, businesses must also comply with ANSI safety signs standards. The American National Standards Institute (ANSI) provides additional guidance on:

-

The proper use of safety symbols

-

The standardization of safety sign colors

-

Consistent design for easy recognition

By following both OSHA and ANSI guidelines, businesses ensure industrial safety compliance while enhancing workplace hazard communication.

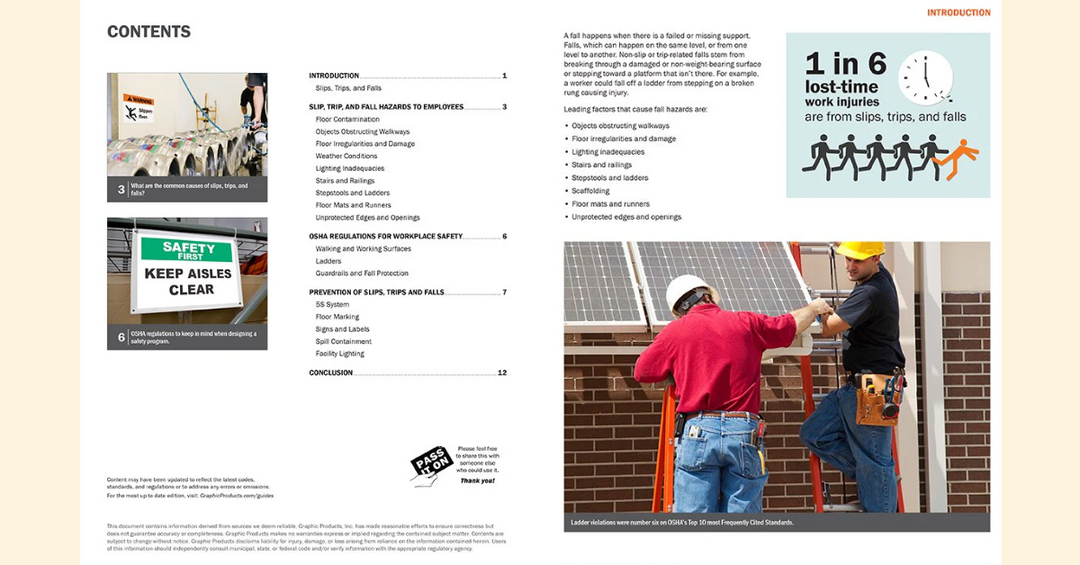

Common Workplace Hazards and How Safety Signs Help

Workplace hazards vary across industries, but some of the most common risks include:

-

Slips, Trips, and Falls – Marked by "Caution: Wet Floor" signs

-

Electrical Hazards – Identified with hazard warning signs for high voltage areas

-

Fire Hazards – Highlighted with fire extinguisher and emergency exit signage

-

Chemical Exposure – Managed with hazardous material labels

By using OSHA-compliant safety signs, businesses can mitigate risks and protect employees from workplace accidents.

How to Choose the Right OSHA Safety Signs

Selecting the correct safety signs depends on workplace conditions and industry regulations. Consider the following factors:

-

Material Durability: Choose weather-resistant signs for outdoor use

-

Legibility: Ensure text is clear and easy to read from a distance

-

Size and Placement: Large enough for visibility in high-traffic areas

-

Industry-Specific Requirements: Follow OSHA standards for specialized industries like construction, healthcare, and manufacturing

Archford offers a wide range of OSHA-compliant safety signs to meet your workplace needs. Visit .Archford to explore our selection.

Best Practices for Maintaining and Updating Safety Signs

Regular maintenance ensures safety signs remain effective and compliant. Follow these best practices:

-

Inspect signs periodically for fading, damage, or obstruction

-

Replace outdated signs with updated versions

-

Ensure proper illumination for emergency exit signs

-

Train employees on the meaning of different safety signs

A well-maintained safety sign system significantly reduces workplace accidents and enhances industrial safety compliance.

Archford: Your Trusted Partner for Workplace Safety

At .Archford, we specialize in providing high-quality, OSHA-compliant safety signs for businesses across various industries. Our safety solutions help companies maintain compliance, improve hazard communication, and create a safer work environment.

Explore our OSHA Safety Signs Guide here: OSHA Safety Signs Guide.

The Ultimate Guide to Workplace Safety: Best Practices for Every Industry

|

Safety Guide |

Tips |

|

Implement Sort, Set in Order, Shine, Standardize, and Sustain for workplace efficiency. |

|

|

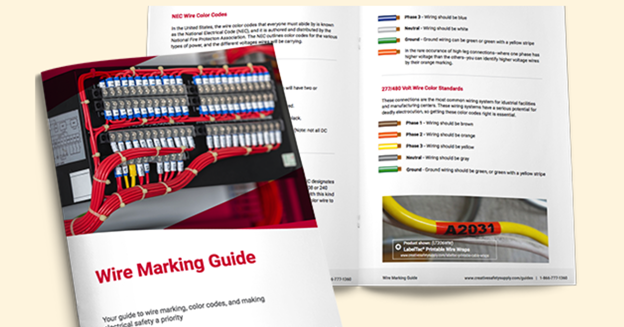

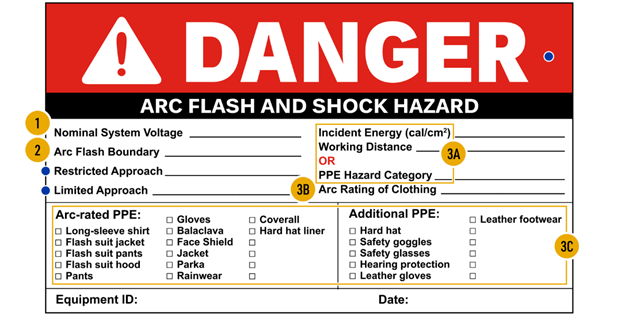

Use proper labels with voltage ratings, approach boundaries, and PPE requirements to ensure electrical safety. |

|

|

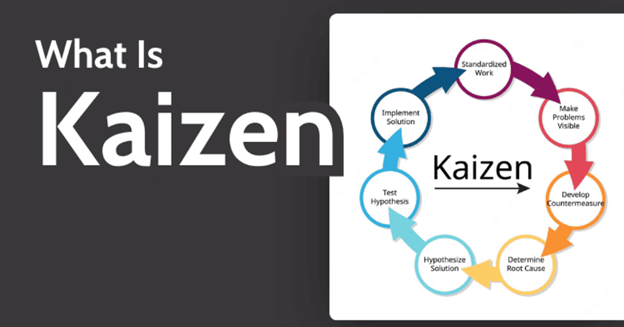

Apply lean methodologies like Kaizen and Six Sigma to enhance operational efficiency. |

|

|

Ensure all hazardous materials are labeled with correct pictograms, signal words, and hazard statements. |

|

|

Use proper lockout devices and tags to prevent accidental energy releases during maintenance. |

|

|

Follow standard color codes and label pipes at regular intervals for easy identification. |

|

|

Place warning signs in high-risk areas to comply with OSHA standards and improve workplace safety. |

|

|

Use AS 1345 standard colors and labels for accurate pipe identification in Australian industries. |

|

|

Add ‘Safety’ to the 5S system to further enhance workplace organization and hazard prevention. |

|

|

Use different colors for specific zones—e.g., red for fire hazards, yellow for caution, and green for safety paths. |

|

|

Encourage small, continuous improvements by involving employees in process optimization. |

|

|

Use visual signals to manage workflow and reduce inefficiencies in production. |

|

|

Implement proper PPE, ventilation, and emergency procedures to ensure worker safety in mining operations. |

|

|

Use durable, heat-resistant labels to prevent misidentification of electrical wiring. |

|

|

Maintain clear aisles, proper signage, and forklift safety measures to reduce accidents. |

|

|

Optimize layout, use barcode scanning, and implement inventory tracking systems for smooth operations. |

|

|

Use consistent signage, color-coded paths, and lighting to improve navigation. |

|

|

Keep floors dry, use anti-slip mats, and mark hazard areas to prevent workplace injuries. |

|

|

Use labels, floor markings, and visual boards to improve communication and organization. |

|

|

Clearly label valves with durable tags to ensure safe and proper operation. |

Conclusion

Implementing the right OSHA safety signs is essential for preventing workplace hazards and ensuring compliance with safety regulations. By understanding the different types of safety signs, placing them strategically, and maintaining them regularly, businesses can enhance workplace safety and protect employees.

For top-quality safety signs and compliance solutions, visit Archford

Frequently Asked Questions (FAQs)

1. Why are OSHA safety signs important?

OSHA safety signs help prevent accidents, communicate hazards, and ensure workplace safety compliance, reducing risks for employees and visitors.

2. How often should workplace safety signs be replaced?

Safety signs should be inspected regularly and replaced when they become faded, damaged, or outdated to maintain visibility and effectiveness.

3. What colors are used for different OSHA safety signs?

- Red – Danger signs

- Orange – Warning signs

- Yellow – Caution signs

- Green – Emergency signs

-

Blue – Information signs

4. Where should OSHA safety signs be placed?

Safety signs should be placed at entry points, work areas, exits, stairwells, and storage areas to alert employees and visitors to potential hazards.

5. Where can I buy OSHA-compliant safety signs?

You can find a variety of OSHA-compliant safety signs at .Archford. Visit www.archford.com.au for high-quality workplace safety solutions.