Floor Marking Colour Chart: Improve Efficiency & Safety

Introduction to Floor Marking Systems

In industrial and commercial workplaces, floor marking plays a crucial role in ensuring safety, efficiency, and organization. Whether in warehouses, manufacturing plants, or healthcare facilities, clear floor markings help guide workers, improve traffic flow, and reduce workplace accidents.

At Archford, we provide a comprehensive Floor Marking Colour Chart to help businesses comply with floor marking regulations and optimize their operations. This guide will explain the importance of floor marking, standard colour codes, and best practices for implementation.

Why Floor Markings Are Essential for Safety and Efficiency

1. Prevents Workplace Accidents

Floor markings provide clear safety markings to workers, alerting them to potential hazards such as restricted areas, moving equipment zones, and emergency exits.

2. Improves Workflow Efficiency

By designating specific paths for pedestrians, forklifts, and machinery, floor markings streamline movement and reduce congestion, enhancing productivity.

3. Enhances Workplace Organization

Proper floor markings help businesses maintain a structured and organized environment, ensuring that tools, equipment, and materials are stored in designated areas.

Understanding the Floor Marking Colour Chart

A Floor Marking Colour Chart is a standardized guide that assigns specific colours to different workplace functions. Understanding these colour codes ensures that employees can quickly recognize and respond to their surroundings, improving visual communication within the workspace.

Standard Colour Codes and Their Meanings

Each colour in a floor marking system serves a distinct purpose. Here are the most commonly used colours and their meanings:

|

Colour |

Meaning |

Application |

|

Yellow |

Caution/Traffic Lanes |

Aisleways, work zones, pathways |

|

Red |

Danger/Fire Equipment |

Fire extinguishers, emergency exits |

|

Blue |

Information/Equipment |

Workstations, equipment storage |

|

Green |

Safety/First Aid |

First aid stations, emergency eyewash |

|

White |

General Storage |

Marking materials, inventory areas |

|

Black & Yellow |

Physical Hazards |

Areas with tripping or impact risks |

|

Red & White |

Keep Clear Zones |

Fire lanes, emergency exits |

Following these standard codes ensures compliance with industrial color standards and improves hazard identification.

Industry Applications of Floor Markings

1. Warehouses and Distribution Centers

Floor markings help direct pedestrian traffic, separate machinery lanes, and designate emergency exits.

2. Manufacturing Facilities

Clearly marked pathways guide workers and vehicles, reducing the risk of collisions and injuries.

3. Hospitals and Healthcare Facilities

Hospitals use workplace color coding to indicate restricted zones, medical storage areas, and emergency routes.

4. Construction Sites

Floor markings highlight dangerous zones, safety walkways, and areas under maintenance.

How to Implement a Floor Marking System

1. Assess Workplace Needs

Identify high-traffic areas, hazardous zones, and key safety locations that require clear markings.

2. Choose the Right Colours

Refer to the Floor Marking Colour Chart to select the appropriate colours for each function.

3. Apply Durable Markings

Use high-quality floor marking tape or industrial paint to ensure long-lasting visibility.

4. Train Employees

Ensure workers understand the meanings of different floor markings and how to respond to them.

5. Regular Maintenance

Inspect markings periodically and replace worn-out labels to maintain floor marking regulations compliance.

Compliance with Safety Standards

In Australia, workplace compliance with industrial color standards is mandatory for reducing risks and ensuring a safe working environment. Following Australian safety standards ensures that floor markings are used effectively to meet legal requirements.

Benefits of Using High-Quality Floor Markings

-

Increases workplace safety by reducing accidents.

-

Enhances operational efficiency through organized movement.

-

Improves hazard awareness for workers and visitors.

-

Ensures compliance with safety markings guidelines.

Common Mistakes to Avoid in Floor Marking

Using Incorrect Colours

Ensure the colours used align with industrial color standards to avoid confusion.

Poor Placement

Avoid placing floor markings too close together, as this can reduce visibility.

Lack of Maintenance

Regularly check for faded or damaged markings and replace them as needed.

Maintaining and Updating Floor Markings

-

Conduct regular inspections to check for wear and tear.

-

Reapply markings in high-traffic areas when necessary.

-

Update workplace color coding to match workplace changes.

The Ultimate Guide to Workplace Safety: Best Practices for Every Industry

|

Safety Guide |

Tips |

|

Implement Sort, Set in Order, Shine, Standardize, and Sustain for workplace efficiency. |

|

|

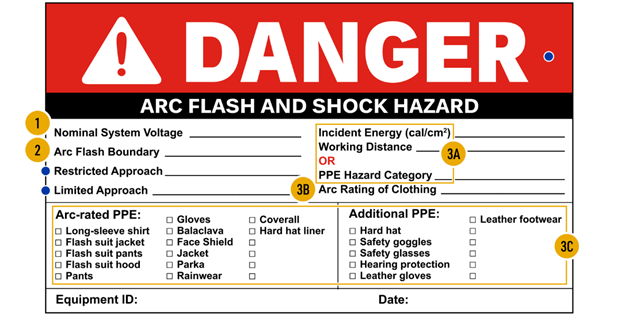

Use proper labels with voltage ratings, approach boundaries, and PPE requirements to ensure electrical safety. |

|

|

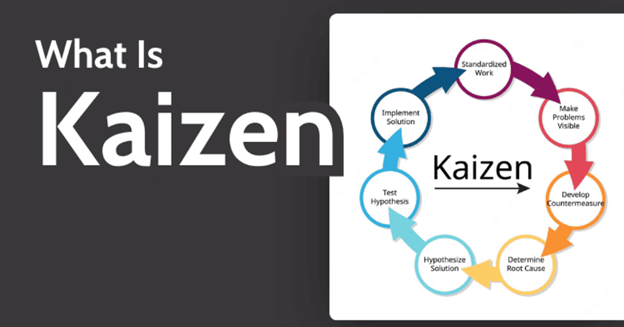

Apply lean methodologies like Kaizen and Six Sigma to enhance operational efficiency. |

|

|

Ensure all hazardous materials are labeled with correct pictograms, signal words, and hazard statements. |

|

|

Use proper lockout devices and tags to prevent accidental energy releases during maintenance. |

|

|

Follow standard color codes and label pipes at regular intervals for easy identification. |

|

|

Place warning signs in high-risk areas to comply with OSHA standards and improve workplace safety. |

|

|

Use AS 1345 standard colors and labels for accurate pipe identification in Australian industries. |

|

|

Add ‘Safety’ to the 5S system to further enhance workplace organization and hazard prevention. |

|

|

Use different colors for specific zones—e.g., red for fire hazards, yellow for caution, and green for safety paths. |

|

|

Encourage small, continuous improvements by involving employees in process optimization. |

|

|

Use visual signals to manage workflow and reduce inefficiencies in production. |

|

|

Implement proper PPE, ventilation, and emergency procedures to ensure worker safety in mining operations. |

|

|

Use durable, heat-resistant labels to prevent misidentification of electrical wiring. |

|

|

Maintain clear aisles, proper signage, and forklift safety measures to reduce accidents. |

|

|

Optimize layout, use barcode scanning, and implement inventory tracking systems for smooth operations. |

|

|

Use consistent signage, color-coded paths, and lighting to improve navigation. |

|

|

Keep floors dry, use anti-slip mats, and mark hazard areas to prevent workplace injuries. |

|

|

Use labels, floor markings, and visual boards to improve communication and organization. |

|

|

Clearly label valves with durable tags to ensure safe and proper operation. |

Conclusion

Implementing a Floor Marking Colour Chart is essential for workplace safety and efficiency. By following standard colour codes, businesses can prevent accidents, improve workflow, and comply with floor marking regulations.

At Archford, we provide high-quality floor marking solutions to help businesses create safer and more efficient workplaces. Visit our Floor Making Colour Chart page to learn more!

Frequently Asked Questions (FAQs)

1. Why are floor markings important in the workplace?

Floor markings improve safety, efficiency, and organization by guiding traffic, marking hazardous areas, and designating storage zones.

2. What colours are commonly used in floor marking systems?

Common colours include yellow for caution, red for fire equipment, green for safety, and blue for informational markings.

3. How often should floor markings be updated?

Floor markings should be inspected regularly and updated whenever they become faded, damaged, or no longer relevant.

4. Are there legal requirements for floor marking in Australia?

Yes, Australian workplaces must comply with floor marking regulations to ensure employee safety and proper hazard identification.

5. Where can I get high-quality floor marking solutions?

Archford provides durable and effective floor marking solutions that meet industrial color standards and workplace safety needs.