Australian Standards Pipe Marking Chart for Industrial Safety

Introduction to Pipe Marking Standards

In industrial environments, ensuring the safety of workers and maintaining workplace compliance are critical. One of the most effective ways to enhance workplace safety is by using a proper pipe identification system. A well-defined system prevents accidents, improves maintenance procedures, and ensures adherence to Australian safety standards.

In Australia, pipe marking regulations dictate how pipelines should be labeled to indicate the type of substances they carry. The Australian Standards Pipe Marking Chart provides clear color codes to help industries comply with safety laws and improve hazard identification.

This blog will explore why pipe marking is essential, how to use the Australian Standards Pipe Marking Chart, and how .Archford provides high-quality solutions to maintain industrial safety compliance.

What is the Australian Standards Pipe Marking Chart?

The Australian Standards Pipe Marking Chart is a visual reference designed to help industries comply with pipe marking regulations. It provides standardized color codes and labels for pipelines transporting various substances such as:

-

Water

-

Gases

-

Chemicals

-

Steam and air

Following this standardized system prevents misidentification, reducing workplace risks and ensuring regulatory compliance.

For businesses looking to adhere to Australian safety standards, .Archford offers a complete pipe marking guide to help you implement a safe and compliant labeling system.

Why Pipe Marking is Essential for Workplace Safety

A proper pipe marking system is not just about compliance—it plays a critical role in workplace safety. Here’s why it is essential:

Prevents Accidents – Workers can quickly identify hazardous pipes, reducing exposure to dangerous chemicals or gases.

Enhances Emergency Response – In case of a leak or spill, emergency responders can easily locate and shut off the affected pipelines.

Improves Efficiency – Maintenance teams can identify pipes faster, reducing downtime and increasing operational efficiency.

Ensures Compliance – Failure to comply with pipe marking regulations can result in fines and penalties. Proper labeling keeps businesses compliant with workplace safety laws.

To ensure your workplace meets Australian safety standards, .Archford provides high-quality industrial safety labels and marking solutions.

Understanding the Color Codes in Pipe Marking

The Australian Standards Pipe Marking Chart uses color codes to indicate the type of substance flowing through the pipes. Some of the most commonly used colors include:

-

Blue – Drinking water

-

Green – Wastewater or sewage

-

Red – Fire-fighting water systems

-

Yellow – Flammable gases

-

Brown – Combustible liquids

-

Black – Air

-

Orange – Acids and alkalis

These color codes for pipes are crucial in helping workers and emergency responders quickly recognize hazards in an industrial environment.

Pipe Marking Regulations and Compliance Requirements

To ensure workplace compliance, industries must follow pipe marking regulations outlined in AS 1345-1995. This standard specifies:

-

Pipe color coding

-

Label placement

-

Font size and text readability

-

Arrows indicating flow direction

Failure to comply with these Australian safety standards can lead to legal issues, safety violations, and increased workplace risks.

Archford offers ready-to-use industrial safety labels that meet Australian safety standards and ensure workplace compliance.

Common Mistakes to Avoid in Pipe Marking

Despite the importance of pipe identification systems, many industries make common mistakes, such as:

Using incorrect colors – Not following standardized color codes can lead to dangerous misinterpretations.

Poor label placement – Labels should be clearly visible and positioned where workers can easily identify them.

Fading or damaged labels – Over time, labels can fade or peel off, making them hard to read. Using high-quality labels from .Archford can prevent this issue.

Lack of employee training – Workers should be trained to understand the markings and respond appropriately to hazards.

By avoiding these mistakes, businesses can maintain an effective pipe marking system and improve overall industrial safety compliance.

Best Practices for Workplace Safety with Pipe Marking

To ensure maximum safety and efficiency, industries should follow these best practices:

-

Use high-visibility labels that can withstand harsh environments.

- Place labels at regular intervals to ensure easy identification from any point.

- Train employees on how to interpret pipe markings correctly.

-

Conduct regular inspections to check for faded or missing labels.

With .Archford’s wide range of industrial safety labels, businesses can effortlessly implement these best practices and stay compliant with Australian Standards.

How Archford Can Help with Pipe Marking Solutions

Archford is a trusted provider of industrial safety solutions in Australia, offering:

-

Pre-printed pipe labels that meet Australian Standard AS 1345-1995

-

Custom pipe marking solutions for unique workplace needs

-

Durable, weather-resistant labels designed for long-term use

-

Guides and resources to help businesses implement workplace compliance

For a complete Australian Standards Pipe Marking Chart, visit Archford today.

The Ultimate Guide to Workplace Safety: Best Practices for Every Industry

|

Safety Guide |

Tips |

|

Implement Sort, Set in Order, Shine, Standardize, and Sustain for workplace efficiency. |

|

|

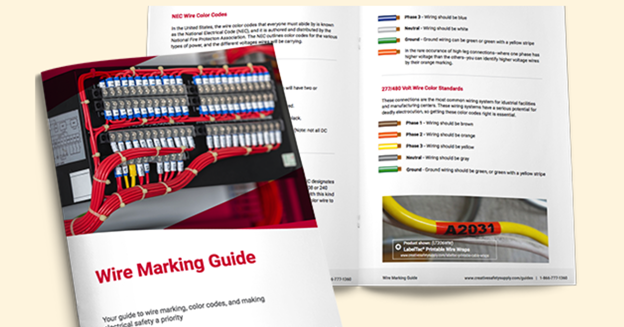

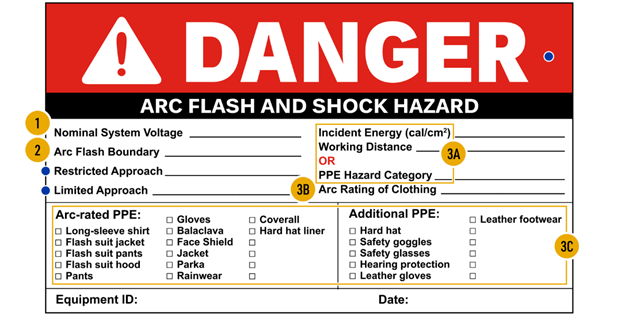

Use proper labels with voltage ratings, approach boundaries, and PPE requirements to ensure electrical safety. |

|

|

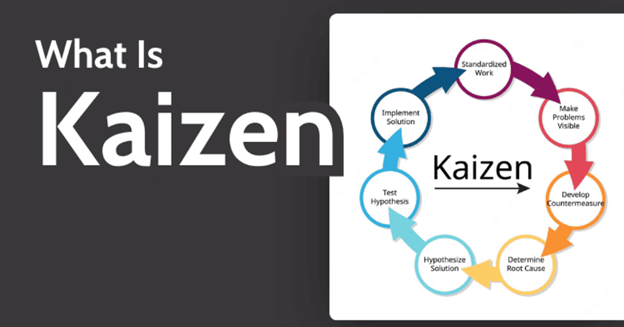

Apply lean methodologies like Kaizen and Six Sigma to enhance operational efficiency. |

|

|

Ensure all hazardous materials are labeled with correct pictograms, signal words, and hazard statements. |

|

|

Use proper lockout devices and tags to prevent accidental energy releases during maintenance. |

|

|

Follow standard color codes and label pipes at regular intervals for easy identification. |

|

|

Place warning signs in high-risk areas to comply with OSHA standards and improve workplace safety. |

|

|

Use AS 1345 standard colors and labels for accurate pipe identification in Australian industries. |

|

|

Add ‘Safety’ to the 5S system to further enhance workplace organization and hazard prevention. |

|

|

Use different colors for specific zones—e.g., red for fire hazards, yellow for caution, and green for safety paths. |

|

|

Encourage small, continuous improvements by involving employees in process optimization. |

|

|

Use visual signals to manage workflow and reduce inefficiencies in production. |

|

|

Implement proper PPE, ventilation, and emergency procedures to ensure worker safety in mining operations. |

|

|

Use durable, heat-resistant labels to prevent misidentification of electrical wiring. |

|

|

Maintain clear aisles, proper signage, and forklift safety measures to reduce accidents. |

|

|

Optimize layout, use barcode scanning, and implement inventory tracking systems for smooth operations. |

|

|

Use consistent signage, color-coded paths, and lighting to improve navigation. |

|

|

Keep floors dry, use anti-slip mats, and mark hazard areas to prevent workplace injuries. |

|

|

Use labels, floor markings, and visual boards to improve communication and organization. |

|

|

Clearly label valves with durable tags to ensure safe and proper operation. |

Conclusion

A well-organized pipe marking system is crucial for industrial safety compliance, regulatory adherence, and efficient operations. By following the Australian Standards Pipe Marking Chart, businesses can:

Reduce workplace accidents

Improve emergency response times

Enhance operational efficiency

Ensure compliance with AS 1345-1995

With .Archford’s high-quality pipe identification system, industries can implement a safe, compliant, and efficient workplace.

FAQs About Pipe Marking Standards

1. Why is pipe marking important in industrial settings?

Pipe marking helps workers and emergency responders identify hazardous substances, ensuring safety and compliance with regulations.

2. What are the standard colors used in Australian pipe marking?

Standard colors include blue for drinking water, yellow for flammable gases, red for fire-fighting water, and black for air.

3. How often should pipe markings be inspected?

It is recommended to inspect pipe markings regularly to check for fading, damage, or missing labels.

4. What regulations govern pipe marking in Australia?

The AS 1345-1995 standard defines the color codes and labeling requirements for industrial pipes in Australia.

5. Where can I get high-quality pipe marking labels?

Archford offers ready-made and custom pipe marking labels that meet Australian safety standards.