Pipe Marking Guide: A Complete Safety Checklist

Introduction to Pipe Marking

Pipes play a crucial role in industrial facilities, transporting liquids, gases, and other essential materials. However, without proper labeling, they can become serious safety hazards. Implementing an effective Pipe Marking Guide ensures that workers and emergency responders can quickly identify pipe contents, reducing the risk of accidents.

This guide will walk you through the importance of pipe marking, best practices, compliance requirements, and how .archford provides high-quality solutions to improve workplace safety.

Why Pipe Marking is Essential for Workplace Safety

An effective pipe labeling system enhances safety by preventing confusion about a pipe's contents. Misidentification can lead to chemical exposure, explosions, or injuries. Proper labeling improves efficiency, allowing workers to perform maintenance and repairs without unnecessary delays.

Additionally, pipe marking ensures workplace safety compliance, helping businesses meet industry regulations and avoid fines or legal issues.

Regulatory Compliance and Industry Standards

Compliance with pipe marking standards is required in various industries, including manufacturing, construction, and healthcare. Organizations such as OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute) have specific guidelines for pipe labeling to improve industrial pipe safety.

Ignoring these regulations can result in penalties and unsafe working conditions, so it’s essential to implement proper marking systems.

Understanding Pipe Marking Requirements

ANSI Pipe Marking Standards

The ANSI pipe marking system is the most widely recognized standard for labeling pipes. It defines:

-

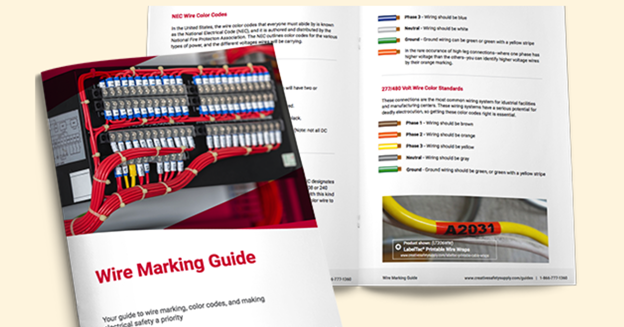

Color codes for pipes to indicate the type of material being transported

-

Placement guidelines to ensure markings are visible

-

Label size requirements for readability

Common Pipe Marking Mistakes to Avoid

To maintain safety and compliance, avoid these common errors:

-

Using incorrect color codes for pipes

-

Placing labels in hard-to-read locations

-

Allowing labels to fade or peel off

-

Failing to update labels after modifications to the piping system

By following industry best practices, businesses can create a reliable and effective labeling system.

How to Implement an Effective Pipe Marking System

1. Identifying Pipes That Require Marking

Not every pipe in a facility requires marking, but any pipe carrying hazardous substances, critical materials, or process-related liquids should have clear identification. These include:

-

Pipes containing flammable gases or toxic chemicals

-

Water supply lines for firefighting or industrial processes

-

Steam or compressed air pipelines

2. Choosing the Right Labels and Materials

Pipe labels must be durable and resistant to heat, moisture, and chemicals. High-quality vinyl labels ensure long-term performance in industrial environments.

3. Correct Placement and Visibility

For labels to be effective, they must be easily visible. Pipe markings should be placed:

-

Near valves and access points

-

At entry and exit points

-

Every 25 to 50 feet along the length of a pipe

Safety Benefits of Pipe Marking

Reducing Workplace Accidents

Clear and standardized labeling prevents accidents by ensuring workers can easily recognize hazardous substances. This is a crucial part of maintaining industrial pipe safety and reducing risks in high-hazard areas.

Ensuring Emergency Response Efficiency

During an emergency, responders must act quickly to control hazards. Proper pipe markings help them identify dangerous materials and take the necessary precautions.

Streamlining Maintenance and Repairs

A well-designed pipe labeling system improves operational efficiency by reducing the time workers spend identifying pipes. This leads to fewer errors and increased productivity.

Pipe Marking Compliance Checklist

Follow ANSI pipe marking standards

Use the correct color codes for pipes

Ensure labels are made of durable materials

Place markings at visible and accessible locations

Regularly inspect and replace damaged labels

Train employees on proper pipe marking practices

Following this checklist ensures a safe and compliant workplace.

How .archford Can Help with Pipe Marking

At .archford, we provide high-quality pipe marking solutions to help businesses meet workplace safety compliance standards. Our durable labels are designed for industrial environments and ensure long-lasting visibility.

For more details, check out our Pipe Marking Guide to learn how to implement an effective labeling system in your facility.

The Ultimate Guide to Workplace Safety: Best Practices for Every Industry

|

Safety Guide |

Tips |

|

Implement Sort, Set in Order, Shine, Standardize, and Sustain for workplace efficiency. |

|

|

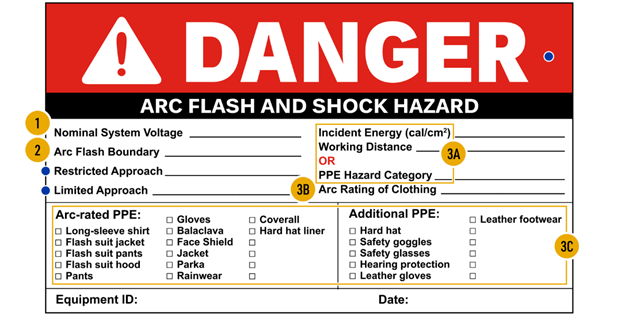

Use proper labels with voltage ratings, approach boundaries, and PPE requirements to ensure electrical safety. |

|

|

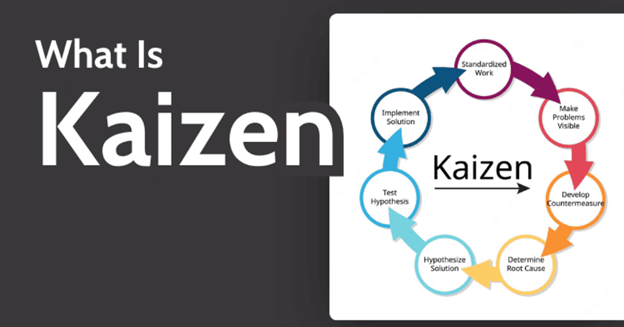

Apply lean methodologies like Kaizen and Six Sigma to enhance operational efficiency. |

|

|

Ensure all hazardous materials are labeled with correct pictograms, signal words, and hazard statements. |

|

|

Use proper lockout devices and tags to prevent accidental energy releases during maintenance. |

|

|

Follow standard color codes and label pipes at regular intervals for easy identification. |

|

|

Place warning signs in high-risk areas to comply with OSHA standards and improve workplace safety. |

|

|

Use AS 1345 standard colors and labels for accurate pipe identification in Australian industries. |

|

|

Add ‘Safety’ to the 5S system to further enhance workplace organization and hazard prevention. |

|

|

Use different colors for specific zones—e.g., red for fire hazards, yellow for caution, and green for safety paths. |

|

|

Encourage small, continuous improvements by involving employees in process optimization. |

|

|

Use visual signals to manage workflow and reduce inefficiencies in production. |

|

|

Implement proper PPE, ventilation, and emergency procedures to ensure worker safety in mining operations. |

|

|

Use durable, heat-resistant labels to prevent misidentification of electrical wiring. |

|

|

Maintain clear aisles, proper signage, and forklift safety measures to reduce accidents. |

|

|

Optimize layout, use barcode scanning, and implement inventory tracking systems for smooth operations. |

|

|

Use consistent signage, color-coded paths, and lighting to improve navigation. |

|

|

Keep floors dry, use anti-slip mats, and mark hazard areas to prevent workplace injuries. |

|

|

Use labels, floor markings, and visual boards to improve communication and organization. |

|

|

Clearly label valves with durable tags to ensure safe and proper operation. |

Final Thoughts

An effective pipe labeling system is essential for safety, compliance, and operational efficiency. By following industry best practices and using high-quality materials, businesses can protect workers, streamline processes, and maintain regulatory compliance.

With the right solutions from .archford, you can create a safer and more efficient workplace.

Frequently Asked Questions (FAQs)

1. What are the key regulations for pipe marking?

Most industries follow ANSI pipe marking standards and OSHA guidelines. These define color codes, label placement, and maintenance requirements.

2. How often should pipe labels be inspected?

Labels should be checked at least once a year or whenever changes occur in the piping system. Regular inspections prevent misidentification and safety hazards.

3. What materials should pipe labels be made of?

Durable vinyl or laminated labels are best for industrial environments. They resist chemicals, moisture, and high temperatures, ensuring long-term performance.

4. Why is color coding important in pipe marking?

Color codes for pipes help workers quickly identify pipe contents, reducing the risk of accidents and ensuring proper handling of hazardous substances.

5. Where can I find high-quality pipe marking solutions?

For reliable pipe labeling solutions, visit .archford and check out our Pipe Marking Guide to learn more.