Warehouse Safety Improvement Tips Every Manager Should Know

Introduction:

Warehouse safety is a critical concern for every manager, as these environments are often bustling with activity, machinery, and a variety of potential hazards.

The importance of implementing comprehensive safety measures cannot be overstated. A safe workplace not only reduces the risk of accidents but also promotes productivity, boosts morale, and protects the company from costly legal and financial repercussions.

In this blog, we'll explore essential warehouse hazard tips that every manager should know. These strategies will help you mitigate risks and create a secure environment for your team.

Common Warehouse Safety Hazards

Before diving into improvement strategies, it’s essential to understand the most common safety hazards found in warehouses. Recognizing these risks will help you take proactive steps to eliminate or reduce them.

Slips, Trips, and Falls

One of the leading causes of workplace injuries in warehouses is slips, trips, and falls. Spilled liquids, uneven flooring, or cluttered walkways can easily cause accidents. Ensuring that floors are dry, well-maintained, and free from obstructions can go a long way in preventing these types of accidents.

Forklift and Equipment Safety

Forklifts are invaluable for moving heavy loads, but they also pose a significant risk if not operated correctly.

Collisions, tip-overs, and pedestrian accidents are all too common. Ensuring that operators are properly trained and that equipment is well-maintained is key to minimizing risks.

Manual Handling Injuries

Lifting and carrying heavy items is a daily task in most warehouses. Improper lifting techniques or failure to use equipment like pallet jacks can result in musculoskeletal injuries. Providing employees with the right tools and training them on proper lifting techniques will help minimize these injuries.

Fire and Chemical Hazards

Warehouses often store hazardous materials, such as chemicals or flammable items. These materials must be handled with care to prevent fires or spills. Proper storage and the availability of fire suppression systems are vital for workplace safety.

Best Practices for Warehouse Safety Improvement

Now that we’ve identified the hazards, let's look at the best practices for improving warehouse safety.

Implement Regular Safety Training

Regular safety training is essential to keeping warehouse employees aware of the risks they face and how to handle them. A thorough training program should cover basic safety procedures, safe equipment operation, emergency response, and specific accident prevention strategies. This ongoing education keeps safety at the forefront of everyone’s minds.

Conduct Routine Safety Inspections

Warehouse safety isn't something that can be overlooked. Routine safety inspections allow managers to identify and address potential hazards before they result in accidents. Using a safety audit checklist ensures all aspects of the warehouse, including equipment, emergency exits, and proper storage, are thoroughly examined and maintained.

Create a Clear Warehouse Safety Plan

A well-documented warehouse safety plan is crucial. It should outline all safety protocols, procedures for handling emergencies, and employee responsibilities. Clear communication about safety expectations will ensure that everyone is on the same page when it comes to preventing accidents.

Improve Lighting and Signage

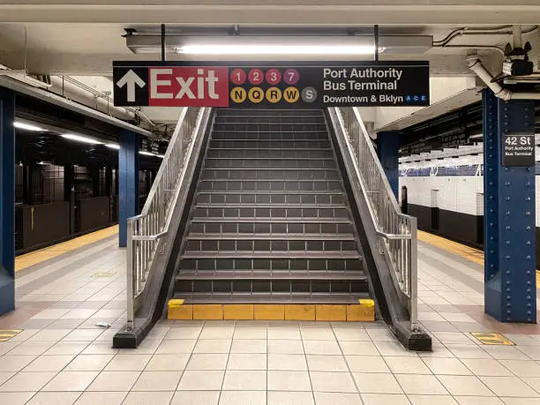

Proper lighting and clear signage are crucial for creating a safe warehouse. Dimly lit areas can hide hazards, while clear, visible signs can direct employees to exits, safety equipment, and hazard zones. Invest in high-quality lighting and ensure that safety signs are easy to spot and read.

Organize and Maintain Clean Work Areas

A cluttered, disorganized warehouse is a recipe for accidents. Ensure that all areas of the warehouse are clean and well-organized. Proper storage, labeling, and keeping tools in designated spots will reduce the risk of accidents caused by misplaced items or obstacles in walkways.

Investing in Safety Equipment and Tools

Investing in the right safety tools is essential for protecting your workforce. The right equipment can help prevent accidents, minimize injury severity, and ensure that your team is prepared for emergencies.

Personal Protective Equipment (PPE)

Personal protective equipment (PPE) should be provided to every warehouse worker. Depending on the specific risks of your warehouse, this could include hard hats, gloves, high-visibility vests, steel-toed boots, and eye protection. Having the right PPE readily available and making sure employees are trained in how to use it properly is a must.

Lockout Tagout Systems for Equipment Safety

One critical tool for warehouse safety is a lockout/tagout system. This ensures that machinery and equipment are properly shut off and cannot be accidentally turned on while workers are conducting maintenance or repairs.

Investing in lockout tools will not only enhance safety but also comply with safety regulations that prevent hazardous energy release. To learn more about lockout/tagout solutions, visit Archford Lockout Tagout.

Fire Extinguishers and Emergency Kits

Having fire extinguishers in strategic locations throughout the warehouse is crucial for preventing and quickly dealing with fires. Along with fire extinguishers, first aid kits should also be stocked with the necessary supplies to deal with common injuries. These safety tools should be checked regularly to ensure they are in good working condition.

Leveraging Technology for Warehouse Safety

Technology can play a huge role in enhancing warehouse safety. From advanced monitoring systems to automated safety equipment, tech solutions can help you manage and mitigate risks more effectively.

Using Warehouse Management Systems (WMS)

A warehouse management system (WMS) helps optimize warehouse operations while improving safety. WMS can track inventory, monitor equipment, and alert managers to safety concerns in real time. Implementing a WMS will not only streamline operations but also help maintain a safer work environment.

Safety Monitoring and Reporting Tools

Investing in safety monitoring tools that allow employees to report hazards or unsafe conditions can prevent accidents. These tools can include apps or devices that enable workers to immediately report any safety concerns to managers or safety officers, ensuring timely intervention.

Engaging Employees in Safety Culture

A safety-conscious workforce is key to minimizing accidents and creating a positive safety culture. Here’s how to engage employees in safety efforts.

Promoting Safety Awareness Among Employees

Employees should be encouraged to actively participate in safety initiatives. Hold regular safety meetings and discussions to keep safety at the top of everyone’s mind. Celebrate safety milestones and recognize individuals who consistently follow safety protocols.

Encouraging Reporting of Safety Concerns

Employees should feel comfortable reporting safety concerns without fear of reprisal. Create an open and supportive environment where workers are encouraged to speak up if they notice potential hazards or unsafe practices.

Explore More: Essential Safety Tips for Every Workplace

|

Safety Tags Tips |

Short Description |

|

Tips for Effective Use of Safety Tags in the Workplace |

|

|

Essential Scaffold Safety Tips for Workers |

|

|

Comprehensive Workplace Safety Tips for Employers |

|

|

A Step-by-Step Lockout Tagout Checklist for Maximum Safety |

|

|

Top Tips for Improving Warehouse Safety Standards |

|

|

Key Safety Tips for Small Businesses |

|

|

Best Practices for Lockout Tagout Procedures |

|

|

The Importance of Fire Safety Signage in Workplaces |

|

|

Essential Personal Protective Equipment (PPE) Tips |

|

|

Best Practices for Scaffold Inspections |

|

|

How to Use Industrial Labeling for Safety and Compliance |

|

|

Construction PPE Safety Tips for Protecting Workers |

|

|

Advanced Safety Tips for a Safer Workplace Environment |

Conclusion

A safe warehouse is not only beneficial for your employees but also for your business. By taking proactive steps to improve warehouse safety, you’re fostering a culture of hazard prevention and ensuring a productive, secure environment.

Investing in quality safety equipment, leveraging technology, and engaging your employees in safety practices are essential for minimizing risks. Most importantly, leadership must set the tone by leading by example and prioritizing safety.

FAQs:

What are the most common warehouse safety hazards?

Common hazards include slips, trips, falls, equipment safety issues, and manual handling injuries.

Why is regular safety training important?

Regular training ensures that employees are well-informed about potential hazards and how to handle them.

How can technology improve warehouse safety?

Technology, such as Warehouse Management Systems and safety monitoring tools, can help track risks, optimize operations, and ensure timely reporting of safety concerns.

What should be included in a warehouse safety plan?

A warehouse safety plan should outline safety protocols, emergency procedures, and the responsibilities of all employees.

How can I engage employees in promoting safety?

Encourage open communication, celebrate safety achievements, and provide incentives for adhering to safety protocols.