Industrial Labeling Tips to Improve Efficiency and Compliance

In an industrial setting, safety and organization are paramount. One of the simplest, yet most effective ways to ensure both is through proper industrial labeling. Not only does labeling help identify equipment and hazards, but it also ensures that workers are compliant with safety regulations. In this blog, we’ll explore the importance of industrial labeling, its benefits, best practices, and how to implement an effective labeling system.

Introduction: The Importance of Industrial Labeling

Industrial labeling involves attaching labels to equipment, machinery, tools, and hazardous materials to communicate vital information and improve operational efficiency. Whether in manufacturing, construction, or warehousing, labeling is crucial for maintaining a safe and organized workspace. By adhering to safety regulations and ensuring clear communication, industrial labels reduce accidents and boost productivity.

Benefits of Proper Industrial Labeling

Efficiency Gains: Clearly labeled equipment and storage areas allow workers to quickly locate tools, machinery, and supplies, reducing downtime and ensuring a smoother workflow.

Compliance with Safety Regulations: Labels, such as hazard signs and equipment identifiers, help meet safety standards like OSHA and ANSI, ensuring that necessary precautions are followed.

Improved Workplace Organization: Proper labeling ensures that everything has its place, preventing confusion and misplacement. This contributes to an organized workspace, which is vital for efficiency.

Essential Types of Labels for Industrial Settings

There are various types of labels that industrial facilities use, each serving a specific purpose. Here are some of the most common types:

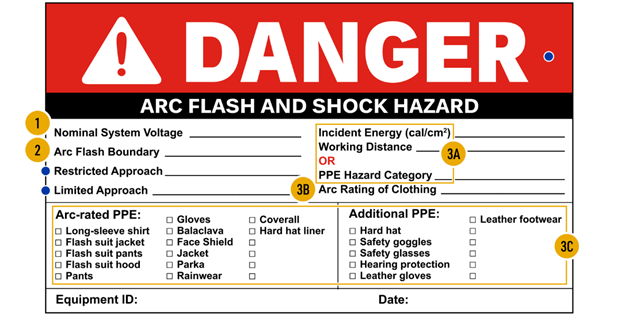

Safety Labels

These labels are used to warn employees about potential dangers and hazards in the workplace. Safety labels typically feature a bright color like yellow or red and include clear symbols or text to alert workers to specific risks, such as chemical exposure, moving machinery, or electrical hazards.

Warning Labels

Warning labels inform workers of potential hazards that could result in injury if precautions aren’t taken. These are commonly used in high-risk areas like construction zones or near heavy equipment. Warning labels often include visual symbols and specific safety instructions, ensuring workers understand the risks before proceeding.

Equipment Identification Labels

These labels help identify tools, machines, and equipment in your facility. Equipment identification labels typically include information such as serial numbers, maintenance schedules, and operating instructions. These labels make it easier to track and maintain machinery, ensuring optimal performance and reducing downtime.

How to Choose the Right Industrial Labels

Selecting the right industrial labels ensures durability and effectiveness. Consider the following factors:

Label Materials: Choose labels made from materials suitable for your environment. For outdoor or high-temperature areas, use weather and heat-resistant labels. For chemical environments, opt for materials resistant to corrosion.

Durability and Environmental Considerations: Labels must withstand extreme temperatures, moisture, and physical wear. Ensure they have strong adhesive properties to prevent peeling or fading.

Customization Options: Custom labels allow you to design labels with logos, symbols, or multi-lingual text, creating a cohesive labeling system for better workplace organization.

Best Practices for Industrial Labeling

- Clear and Readable Labels: Use bold fonts, high-contrast colors, and universally recognized symbols to enhance visibility and understanding.

- Consistent Labeling: Maintain uniform label formats and placements across the facility to improve efficiency and reduce confusion.

- Strategic Placement: Position labels in easily visible locations, such as eye level in high-traffic areas, avoiding obstructions.

Compliance and Safety Regulations

OSHA and ANSI set standards for industrial labeling, requiring hazard labels to follow specific color and symbol guidelines to ensure workplace safety and regulatory compliance.

How to Implement an Effective Labeling System

To implement an effective labeling system, you need to establish a clear labeling workflow. Start by determining the areas and equipment that require labeling. Create a labeling schedule and assign specific employees to manage the labeling process. It’s also important to train employees on how to interpret labels and understand the information presented.

Common Labeling Mistakes to Avoid

Even the best-laid plans can go awry if you make common labeling mistakes. Here are a few things to avoid:

Overcrowding Information

Labels with too much text or too many symbols can overwhelm workers. Keep labels concise and to the point, providing only the most important information.

Poor Label Placement

Placing labels in hard-to-reach or obscured locations can lead to confusion or failure to notice hazards. Always ensure that labels are placed in visible and accessible spots.

Using Low quality Material

Choosing cheap or low-quality materials can lead to labels that fade, peel, or become illegible over time. Invest in durable materials that can withstand your facility’s environment and last over time.

Technological Advancements in Industrial Labeling

In recent years, there have been advancements in industrial labeling technology that make the process more efficient and accurate.

Digital labeling systems, for instance, allow for easier customization and higher-quality prints. Additionally, automation in the labeling process can streamline the process, especially for large facilities with a high volume of products or equipment.

Explore More: Essential Safety Tips for Every Workplace

|

Safety Tags Tips |

Short Description |

|

Tips for Effective Use of Safety Tags in the Workplace |

|

|

Essential Scaffold Safety Tips for Workers |

|

|

Comprehensive Workplace Safety Tips for Employers |

|

|

A Step-by-Step Lockout Tagout Checklist for Maximum Safety |

|

|

Top Tips for Improving Warehouse Safety Standards |

|

|

Key Safety Tips for Small Businesses |

|

|

Best Practices for Lockout Tagout Procedures |

|

|

The Importance of Fire Safety Signage in Workplaces |

|

|

Essential Personal Protective Equipment (PPE) Tips |

|

|

Best Practices for Scaffold Inspections |

|

|

How to Use Industrial Labeling for Safety and Compliance |

|

|

Construction PPE Safety Tips for Protecting Workers |

|

|

Advanced Safety Tips for a Safer Workplace Environment |

Conclusion:

The Role of Labeling in Safety and Operational Success

Industrial labeling is an essential component of workplace safety and operational efficiency. By following best practices and investing in the right labeling system, you can enhance communication, improve safety, and meet regulatory compliance. Proper labeling not only reduces accidents but also ensures smooth operations and better organization within your facility.

By utilizing a workplace label guide and investing in custom industrial labels, you can create a safer, more organized, and efficient working environment. Clear, compliant, and consistent labeling enhances safety, promotes workplace hazard reduction, and contributes to an efficient workspace organization.

For more information on labeling products, check out our industrial labels and tags page to find solutions tailored to your needs.

FAQs

Why is industrial labeling important?

Industrial labeling is vital for ensuring safety, improving efficiency, and maintaining compliance with safety regulations. Labels communicate vital information about hazards, equipment, and safety procedures.

What types of labels are used in industrial settings?

Common types of labels include safety labels, warning labels, and equipment identification labels, each serving a specific purpose in maintaining safety and organization.

How do I choose the right industrial labels?

Consider the environment, material durability, and customization options when selecting labels. Ensure they are made from materials that can withstand harsh conditions.

What are some best practices for labeling?

Some best practices include ensuring labels are clear and readable, maintaining consistency across the facility, and strategically placing labels in high-visibility areas.

Are there industry standards for labeling?

Yes, OSHA and ANSI provide guidelines for labeling, ensuring that labels meet specific safety and communication standards for clarity and effectiveness.