Best Practices for Safety Floor Markings in Manufacturing Facilities

Maintaining safety in a manufacturing facility is crucial to protect employees, enhance productivity, and ensure smooth operations. One of the most effective methods for improving workplace safety is through the use of safety floor markings. These markings clearly define hazardous areas, guide employees, and prevent accidents. This blog will walk through the best practices for safety floor markings and how to integrate them effectively in manufacturing environments.

Introduction

Safety floor markings serve as visual cues that inform workers of designated walkways, restricted areas, and potential hazards. By incorporating appropriate markings and adhering to safety floor marking standards, manufacturing facilities can minimize accidents and improve operational efficiency.

Types of Safety Floor Markings

Color Coding for Safety Zones

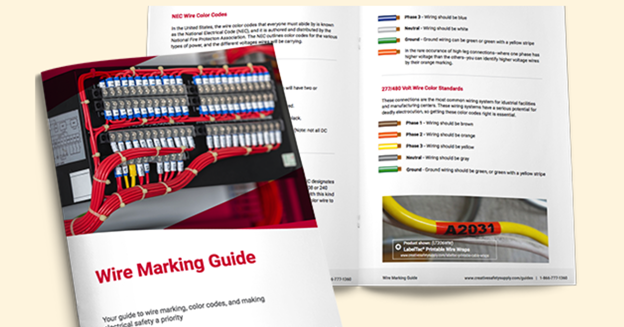

Different colors are used to indicate various safety zones and guidelines. For instance, yellow typically marks walkways, red is used to highlight fire hazards, and green indicates safe zones. Using color-coded markings that align with safety floor marking standards is crucial for clear communication across the facility.

Durable Materials for Floor Markings

Floor markings should be durable enough to withstand heavy foot traffic and machinery. Popular options include 5S tape and warehouse floor safety tape, both designed for long-term use. These materials ensure that markings remain visible and effective even in busy industrial environments. Additionally, using 3M reflective tape can enhance visibility in low-light areas, further improving safety.

Best Practices for Application

Placement for Most extreme Visibility

Floor markings must be placed deliberately to ensure tall visibility. Key zones like passages, high-traffic zones, and close gear ought to be stamped. For instance, putting markings near areas requiring security apparatuses like an electrical lockout pack ensures that laborers are always mindful of potential hazards.

Avoiding Packing of Markings

It's basic to avoid overcrowding the floor with as well numerous markings, as this can confuse employees. Stick to the basic markings that direct workers, like path demarcations and risk pointers, and restrain superfluous visuals. Stuffed markings can diminish the clarity of the message and increase the probability of accidents.

Compliance with Safety Standards

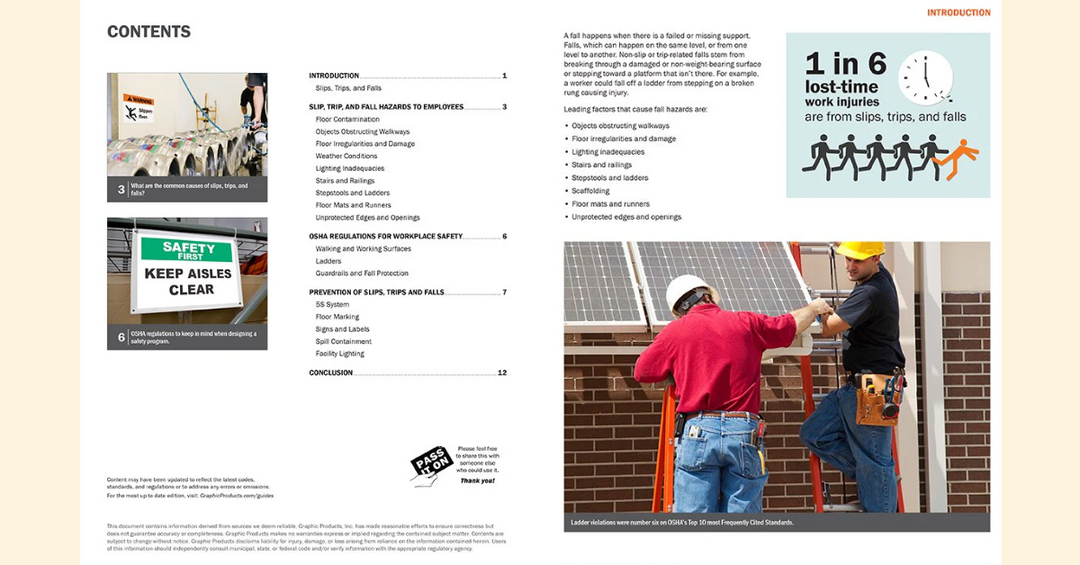

OSHA Guidelines

Compliance with OSHA rules is a must for any manufacturing facility. OSHA provides clear instructions on utilizing floor markings to separate work regions, define pathways, and stamp hazards. This includes ensuring that markings used for security purposes, like those near rigging ranges or around lifting zones, comply with rigging labels and security standards.

Industry Best Practices

Beyond OSHA, adhering to industry best practices improves overall office safety. For instance, adding Dot tape to vehicles and storage areas ensures compliance with federal regulations and improves visibility, especially in ranges where large gear is used.

Employee Training and Awareness

Importance of Clear Communication

All workers must understand the meaning behind the various floor markings and how they relate to their security. For this case, workers ought to be prepared to recognize areas stamped with distribution center floor safety tape or 5S tape as assigned walkways or caution zones. They ought to too be mindful of where to find basic equipment, like an electrical lockout pack, in case of an emergency.

Regular Safety Walkthroughs

Performing standard security walkthroughs ensures that floor markings stay obvious and effective. During these reviews, it's too imperative to check the condition of markings and ensure employees are following safety protocols. Tools such as a smart gate bolt can be used to secure limited areas and reinforce safety measures in hazardous locations.

Maintenance and Inspections

Regular Reviews for Checking Integrity

Over time, floor markings can blur, peel, or become damaged. Regular audits help identify areas where markings need to be refreshed. For example, using 3M reflective tape for regions with destitute lighting can improve safety by ensuring the markings are obvious in all conditions. Also, checking for wear and tear on warehouse floor security tape guarantees the life span of your security checking system.

Replacing Worn-out Markings

When floor markings become worn, they should be replaced immediately to keep up a secure environment. Tough alternatives like 5S tape and Dab tape are amazing for long-lasting execution. Replacing blurred or damaged markings regularly ensures that your facility remains in compliance with both safety floor marking standards and inner safety guidelines.

To sum up

Safety floor markings are essential for maintaining a safe and efficient manufacturing facility. Following best practices, such as adhering to safety floor marking standards, using durable materials like 5S tape, and performing regular maintenance, helps reduce accidents. Enhancing safety with tools like 3M reflective tape and a smart gate lock further protects workers.

Ensuring employees are well-trained and markings are properly maintained not only ensures compliance but fosters a culture of safety. Using safety tools like electrical lockout kits, rigging tags, and clear markings keeps everyone aware of potential hazards.

FAQs

- Why are safety floor markings essential? They prevent accidents, guide workers, and highlight hazards in manufacturing facilities.

- What materials should be used? 5S tape and warehouse floor safety tape are durable options for industrial settings.

- How to ensure compliance with safety standards? Follow OSHA guidelines and industry-specific safety floor marking standards.

- How often should markings be maintained? Regular checks and timely replacements keep markings effective.

- What other tools improve safety? Use electrical lockout kits, rigging tags, 3M reflective tape, and smart gate locks for added protection.