Customizing Your Electrical Lockout Kit for Specific Industries

Ensuring safety in any workplace that deals with electrical systems is critical, and electrical lockout kits are a fundamental part of that safety protocol. However, different industries have unique requirements when it comes to lockout/tagout procedures. Customizing your kit based on industry-specific needs ensures maximum safety and compliance. Below, we’ll explore how to tailor your lockout kit for different industries, while integrating essential tools like labeling and reflective safety tape.

Introduction – Why Customize?

Customizing your electrical LOTO kit is essential because each industry faces unique risks and requires specific tools to mitigate them. For instance, a factory environment demands heavy-duty lockouts for large machinery, while a healthcare facility may need specialized solutions for medical equipment. A well-designed lock-out tag-out kit reduces accidents, ensures regulatory compliance, and streamlines procedures in critical situations.

Industry Needs

Manufacturing: Factories and industrial settings often involve high-voltage equipment and heavy machinery. Custom kits should include durable lockout gadgets and clear labeling systems, supported by tools like a name printer to make exact, long-lasting labels for machinery and electrical components. It's also crucial to utilize combination locks for securing different gadgets safely.

Construction: Workers in construction often move between different sites. They need portable and flexible electrical LOTO units with clear instructions and safety tags. Reflective floor tape can be useful for marking hazardous zones and guaranteeing that lockout points are highly visible indeed in low-light conditions.

Oil & Gas: In this high-risk environment, safety is a top priority. Custom kits with valve lockouts and safety markers like intelligent floor tape help ensure that all workers are aware of hazards, even in dangerous conditions. Valve lockouts and clear labeling systems can prevent accidental equipment activation.

Healthcare: Hospitals and clinics depend on exact lockout strategies to avoid interruptions in the operation of life-saving gear. Custom names from a name printer are basic for organizing and marking devices. Additionally, incorporating a programmed hand sanitizer container into workstations ensures hygiene while handling critical equipment.

Standard Components – Padlocks, Tags, Breakers

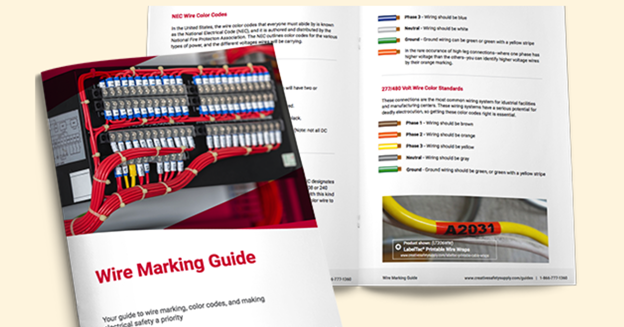

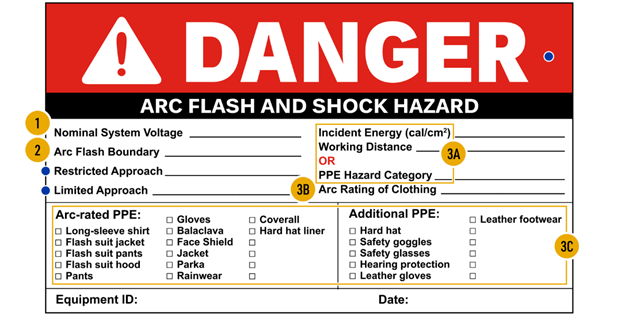

Basic components like padlocks, lockout hasps, breaker lockouts, and safety tags are essential in all industries. Whether in manufacturing, healthcare, or development, these components shape the establishment of any viable electrical lockout pack. Utilizing combination latches can give secure, versatile solutions for locking out multiple devices. A label printer is critical for creating durable, easy-to-read labels that help identify equipment, lessening the risk of accidental re-energization.

Custom Solutions – Industry-Specific Lockouts

Customization is key to ensuring your lockout/tagout kit is fit for purpose:

Manufacturing: Use heavy-duty locks and devices to protect large machines and electrical systems. Labels created with a named printer ought to clearly distinguish each lockout point, while reflective floor tape can enhance visibility around danger zones.

Construction: Portable lock-out tag-out kits with clear, durable labels and reflective markers are essential for safety on the move.

Oil & Gas: Valve lockouts, strengthened latches, and high-visibility labels and tape are significant in high-risk environments.

Healthcare: Specialized lockout arrangements for delicate therapeutic gear ought to be clearly labeled and simple to utilize. Coordination of programmed hand sanitizer containers makes a difference keep up cleanliness around workstations and equipment.

Tag Options – Label Printer and Reflective Floor Tape

Effective labeling is one of the most important aspects of a lockout/tagout system. A label printer ensures that all lockout focuses are marked with customized, long-lasting names. Moreover, reflective floor tape can be utilized to highlight dangerous zones or regions that ought to stay clear amid lockout procedures, increasing overall safety.

Maintenance & Training

Regularly keeping up and updating your electrical LOTO unit is essential to ensuring safety and compliance. Preparing employees on how to use the bolt-out tag-out units, apply names, and utilize intelligent floor tape helps ensure that the framework works proficiently in crises. Incorporating hygiene arrangements like automatic hand sanitizer dispensers is also recommended, especially in

Conclusion – Maximizing Safety

Customizing your electrical lockout kit ensures that your workplace adheres to industry-specific safety standards. Whether in manufacturing, construction, healthcare, or oil & gas, utilizing devices like intelligent floor tape, a named printer, and automatic hand sanitizer dispensers will help make a safer, more efficient environment for all specialists.

FAQs:

- What is an electrical lockout kit?

A kit used to safely isolate energy sources during maintenance.

- Why customize a kit for industries?

Customizing ensures the kit meets specific safety needs for different sectors.

- Which industries need customized kits?

Manufacturing, construction, oil & gas, and healthcare benefit from tailored lockout kits.

- Why use a label printer?

To create clear, durable labels for marking lockout points.

- How does reflective floor tape help?

It enhances the visibility of hazardous areas.