The Role of Inspection Tags in Ensuring Construction Site Safety

Construction destinations are energetic situations where security is a vital concern. With various pieces of overwhelming apparatus, instruments, and gear in steady utilization, the potential for mishaps and dangers is ever-present. Guaranteeing that all gear is in appropriate working condition and that security conventions are taken after is basic to anticipating mischances and keeping up a secure working environment. This is where Inspection tags come into play.

In this web journal post, we will investigate the part of these labels in development location security, their different applications, and how they contribute to a more secure and more productive work environment. We will moreover talk about best hones for actualizing a compelling review labeling framework and how these tags interact with other security measures such as Rigging tags, Lockout units, and intelligent tape.

Understanding Inspection Tags and Their Importance

Inspection tags are names or labels joined to gear, devices, and apparatus to demonstrate their review status, upkeep history, and security compliance. They give a visual affirmation that the hardware has been assessed and is secure to utilize. These labels ordinarily incorporate data such as the date of the final review, the title of the auditor, and any notes or comments about the equipment's condition.

Applications of Inspection Tags on Construction Sites

These labels are utilized in different ways on development destinations to upgrade security and compliance. Here are a few of the key applications:

- Equipment and Apparatus Inspection

The most common utilization of these labels is for observing the condition of heavy equipment and machinery. Development locales depend intensely on machines like cranes, excavators, bulldozers, and control devices. Normal reviews are fundamental to guarantee that these machines are working accurately and do not pose a security chance. Assessment labels joined to each piece of hardware give a clear record of when the final review happened and whether the hardware is secure to operate.

- Fall Protection Equipment

Fall protection equipment, such as tackles, lanyards, and stay focused, is basic for specialist security on hoisted stages. These things must be reviewed routinely to guarantee they are free from harm and wear that may compromise their adequacy. Labels on drop assurance gear show that it has been checked and are secure for utilization, giving specialists the certainty they require to perform their errands at height.

- Electrical Systems

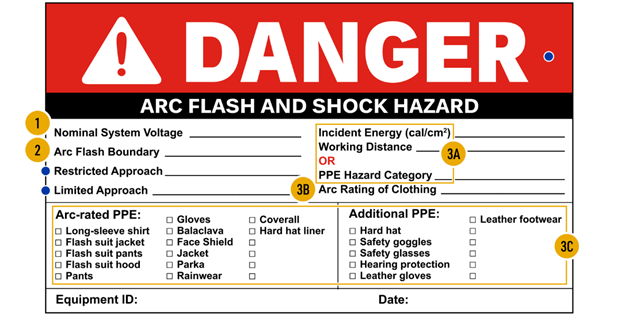

Electrical systems are another zone where labels play a pivotal part. Electrical panels, wiring, and outlets must be frequently assessed to ensure they are secure and compliant with regulations. Tags on electrical components show that an assessment has been conducted, and any issues have been addressed. This is particularly vital when working with Lockout packs and lock-out tag-out locks to guarantee that electrical systems are securely de-energized amid maintenance.

- Rigging and Lifting Equipment

Rigging and lifting operations include noteworthy dangers, and the hardware utilized in these assignments must be in fabulous condition. Fixing labels connected to slings, chains, snares, and other fixing hardware affirm that these things have been reviewed and are secure for use. These labels are basic for anticipating mischances amid lifting operations, which can result in extreme wounds or fatalities.

The Part of Assessment Labels in Security Compliance

In expansion to their viable applications, these labels play a crucial part in guaranteeing compliance with security controls. Administrative bodies, such as WorkSafe Australia, command that development companies actualize thorough review and upkeep programs to protect specialists from dangers. Disappointment to comply with these directions can result in fines, legitimate activity, and, most vitally, an expanded chance of accidents.

Best Practices for Implementing an Inspection Tagging System

To maximize the viability of these labels on your development location, it's basic to actualize a strong labeling framework. Here are a few best phones to consider:

- Standardize Your Tags

Standardization is key to guaranteeing that labels are effortlessly recognizable and caught on by all specialists. Utilize a steady arrange for your labels, counting areas for the review date, inspector's title, hardware ID, and any notes. Color-coding your labels can moreover offer assistance separate between distinctive sorts of hardware or review statuses.

- Regular Training

Workers ought to be prepared for the significance of these labels and how to translate the data on them. Preparing ought to cover how to apply labels, what to do if they experience hardware without a tag, and the steps to take if they discover an out-of-date or harmed tag. Normal refresher preparation guarantees that everybody on the location remains watchful and mindful of the labeling system.

- Routine Audits

Conduct schedule reviews of your assessment labeling framework to guarantee that all hardware is accurately labeled and that reviews are being performed as planned. Reviews ought to too confirm that labels are clear, up-to-date, and safely connected to the gear. Any disparities ought to be tended to instantly to keep up the keenness of the system.

Integrate with Other Safety Measures

These labels ought to be coordinated with other security measures on your site, such as Lockout kits and Reflective tape. For example, when the hardware is bolted out for maintenance, the tags should demonstrate that the gear is not to be utilized until the lockout is expelled. Similarly, labels on hardware found in low-light zones can be improved with intelligent tape to guarantee they are unmistakable at all times.

The Impact of Inspection Labels on Workplace Culture

Beyond their utilitarian benefits, these labels contribute to a culture of security in development locales. When laborers see that gear is routinely reviewed and labeled, it strengthens the message that security is a beat need. This can lead to expanded carefulness and adherence to security conventions, as specialists are more likely to follow suit when they see that the company is committed to keeping up a secure environment.

Conclusion

Inspection labels are a vital apparatus for guaranteeing development location security. By giving a clear record of hardware assessments, these labels help anticipate the utilization of hazardous gear, diminish the hazard of mishaps, and guarantee compliance with security controls. Actualizing a strong inspection tagging framework, upheld by standard preparation and reviews, can altogether improve the security and productivity of your development site.

Incorporating Rigging tags, Lockout packs, and Intelligent tape into your security conventions, near these labels, will advance and reinforce your site's security measures. By prioritizing the utilization of these tags, you are taking a proactive step toward securing your laborers and making a safer, more productive work environment.